Self-leveling compound | Price, DIY, Advice and Info

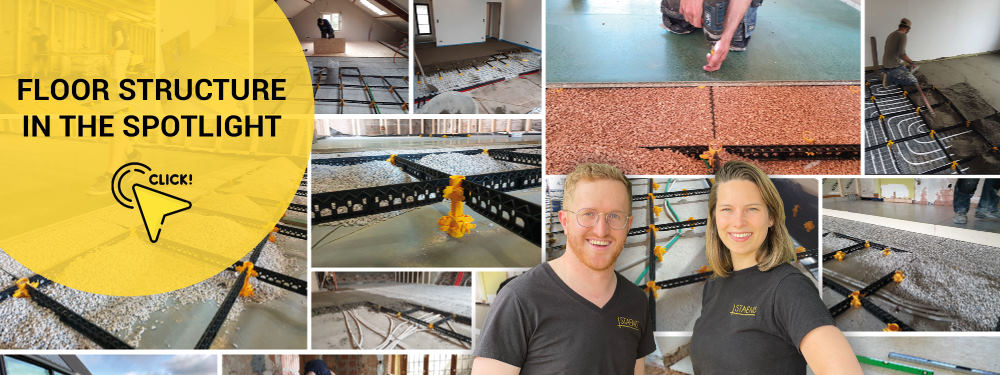

Would you like to install self-leveling compound yourself? It is important to have a good base for a perfect floor finish. With the Staenis leveling grid, you can easily and reliably create a flat subfloor at the correct height.

The grid also reinforces the substrate, making your floor finish better protected against cracks. For heights between 1 mm and 2 cm, we recommend using self-leveling compound in the Staenis leveling grid. However, there are also self-leveling compounds that can be applied up to a height of 5 cm.

For heights between 1 cm and 5 cm, it is more advantageous to install a bonded screed floor. Self-leveling compound is always applied as a bonded layer, so using the correct primers is essential. We are happy to assist you further with this!

Applications

On concrete or screed: Self-leveling compound can be applied to eliminate any irregularities or height differences and to create a smooth and even substrate.

On existing tiling: Self-leveling compound can help to hide any irregularities or cracks in the existing tiling and create a smooth surface for further finishing.

Blogs (guides)

Possible self-levelling floor constructions

Bonded screed as an alternative to self-leveling compound

What is leveling compound and how do you use it?

Self-leveling compound is a self-leveling material that mainly consists of cement and plastics. It provides a flat and smooth surface on the floor and prevents cracks and fissures. Self-leveling compound is suitable for various substrates, such as existing tiling, concrete, or cement screeds. The thickness of self-leveling compound varies from 1 to 50 mm, depending on the substrate and the type of compound. When preparing the self-leveling compound, it is important to use the correct water ratio and to ensure the substrate is clean, dry, dust- and grease-free. After applying the self-leveling compound, you must wait until it has sufficiently cured, after which it is suitable for further finishing.

Egaline, an effective leveling compound

To level your floor, you need a leveling compound, such as self-leveling compound. Self-leveling compound is a liquid, cement-like material made of synthetic resins. It can be used on sand-cement and anhydrite subfloors. Self-leveling compound is available as a powder that you mix with water. The self-leveling mix is liquid while working, but hardens after application. The mixture adheres quickly to the substrate, so it is important to work carefully right away, as removing this layer is difficult.

Why use self-leveling compound?

By applying a layer of self-leveling compound, you get a good subfloor without level differences on which you can place a new finishing layer. With self-leveling compound, you can compensate for level differences up to 3 cm. This way, you can even raise part of your underlying floor to the level of the entire floor slab. For floors higher than 30 millimeters, it is better to install a bonded screed with the Staenis Egalinerooster. For floors in very poor condition, it is better to use another building material than self-leveling compound or leveling mortar. Consult a professional for the right approach. Leveling mortar/smoothing mortar is in fact also self-leveling compound, but usually a type that does not flow open by itself. You therefore have to spread leveling mortar open and flat yourself.

Levelling: don't forget your primer

Before leveling or smoothing a screed subfloor, you should apply the appropriate floor primer. Priming your floor is essential for a durable and even surface. The primer strengthens the top layer, ensures better adhesion of the leveling compound, and prevents the leveling compound from drying too quickly on the absorbent substrate. The primer also ensures that the leveling compound flows out better and can perform optimally during application.

On which substrate do you apply leveling compound?

Self-leveling compound can be applied to many different substrates, such as existing tile work, concrete, or cement screeds. Make sure that the substrate is stable, clean, dry, and free of dust and grease. Also remove substances that could negatively affect adhesion. Always use a suitable primer (bonding primer).

Which self-leveling compound should I buy?

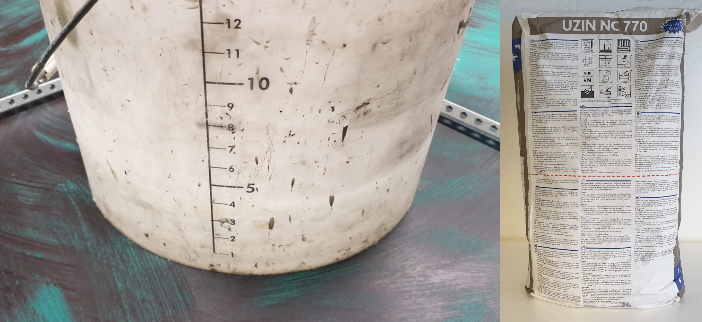

You choose self-leveling compound based on the height difference you want to even out. If you need to level about 1 cm in height, choose a self-leveling compound between 1 mm and 2 cm. This gives you some leeway and the compound will flow nicely at that height. Always read the technical data sheet to check the compatibility between the substrate, self-leveling compound, and floor finish.

How do you apply leveling compound with the Staenis leveling grid?

Follow these steps to apply leveling compound using the Staenis leveling grid:

- Make the surface clean, dry, dust- and grease-free.

- Apply a suitable bonding primer to the substrate and allow it to dry according to the instructions on the packaging.

- Place the Staenis leveling grid on the floor according to the supplied instructions.

- Mix the leveling compound with water according to the recommended ratios on the packaging.

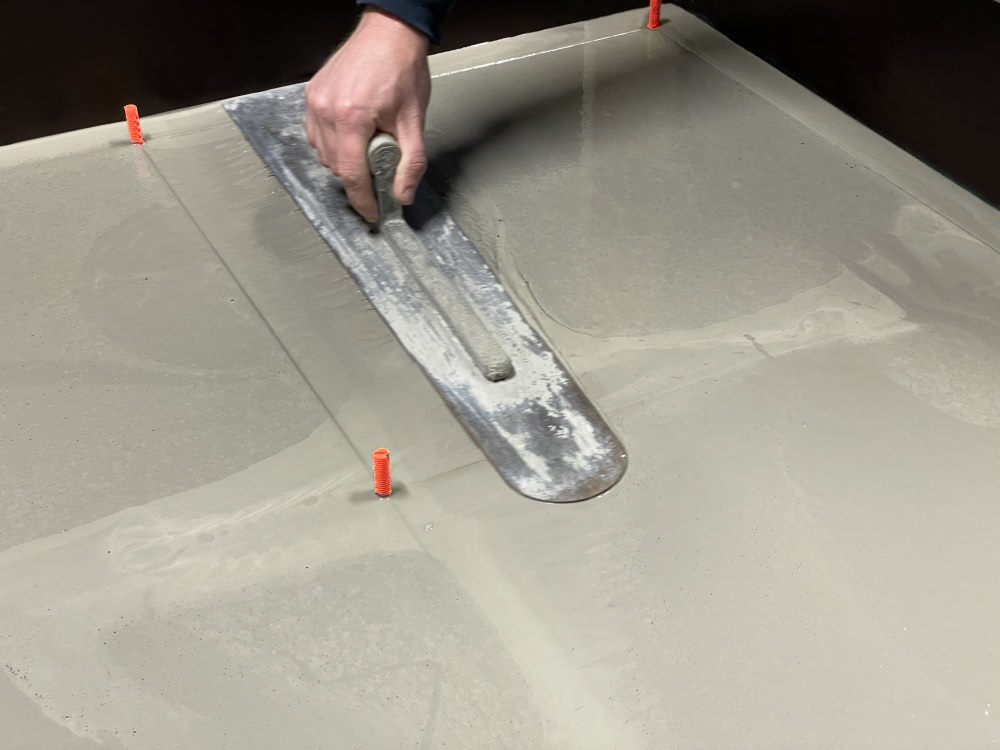

- Pour the leveling compound mixture onto the floor and within the Staenis leveling grid. Spread it evenly with a trowel or squeegee.

- Let the leveling compound dry and cure according to the recommended time on the packaging.

Frequently asked questions

With self-leveling compound, the difficulty lies in pouring the correct amount of compound in the right place. The leveling grid helps enormously to solve exactly that difficulty. You pour the compound level with the top of the grid. If you visually see that the grid is sticking out somewhere, you can pour some more compound there.

The thickness of a standard leveling compound is limited: it usually ranges between 1-50mm. This depends on the substrate and the type of leveling compound.

You can find this on the packaging. When preparing the leveling compound, use the correct water ratio, as this is essential. Too much or too little water will reduce the product properties.

Yes and no! With the StaenisGrid leveling grid in combination with tiles and floating floor coverings, you do not need to vent the leveling compound. In all other situations, it is recommended to use a spiked roller, as this benefits the flow of the leveling compound.

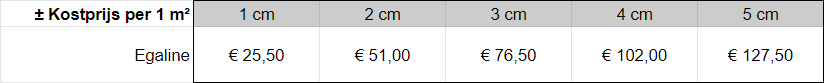

The price of leveling compound varies depending on the brand, quality, and quantity.

The average drying time of leveling compound before it has cured enough for the finishing floor is between 12 and 48 hours. Most floors are walkable after about four hours. The drying time depends on the type of leveling compound, the subfloor, ventilation, and the thickness of the leveling compound floor.

Can't manage to apply the desired layer thickness in one go? Then consider leveling twice. Before applying the second layer of leveling compound, make sure the first layer has dried. Apply a primer between the two layers of leveling compound. Always read the packaging for this, as it may vary by manufacturer.

The drying of leveling compound can vary depending on the product, the thickness of the layer, and the environmental conditions. In general, it takes at least 24 hours for leveling compound to be sufficiently dry to continue working. Always consult the product packaging for the specific drying time.

It is possible to apply leveling compound on a wooden floor, but you need to take special precautions to ensure good adhesion and to accommodate movement in the wooden floor. For this, use a special leveling compound for wooden floors and a suitable bonding primer.

The required amount of leveling compound depends on the surface area and the thickness of the layer you want to apply. To calculate this, first measure the length and width of the room. Multiply these two values to obtain the total surface area in square meters. Then determine the desired thickness of the leveling compound in millimeters. Consult the packaging of the leveling product for the consumption per square meter per millimeter thickness. Multiply the surface area by the consumption and the desired thickness to calculate the total required amount of leveling compound in kilograms. Or use our handy calculator on our website.

Yes, self-leveling compound is suitable for underfloor heating. It offers excellent thermal conductivity and ensures an even heat distribution across the floor. Make sure to choose a self-leveling product that is compatible with underfloor heating and take the proper preparations, such as applying a suitable primer and checking the heating pipes for leaks before applying the self-leveling compound.

Removing self-leveling compound can be difficult because it is a hard and strongly adhesive material. Depending on the thickness and adhesion of the self-leveling compound, you can use different methods to remove it:

Manual removal: Use a hammer and chisel or a putty knife to carefully pry and remove the leveling compound. This can be labor-intensive and time-consuming, but it is an option for small surfaces or thin layers of leveling compound.

Use a floor scraper: A floor scraper is an electric tool specifically designed to remove hard materials such as self-leveling compound, tile adhesive, and concrete from floors. This is a faster and more efficient method, especially for larger surfaces and thicker layers of self-leveling compound.

Grinding: In some cases, it may be necessary to use a concrete grinder or floor grinding machine to remove the leveling compound. This is an effective method, but it can create dust and noise and may damage the underlying floor if you are not careful.

When removing leveling compound, it is important to always take the necessary safety precautions, such as wearing eye and hearing protection, gloves, and dust masks.

Calculator and prices

Customer enquiries

Discover how to correctly dose underfloor heating additive when preparing screed with the Staenis silo for optimal results.