Load-bearing dry infill floor structure

Information

Advantages

- Achieve a perfect end result without experience

- Directly boardable with double staggered Durelis or OSB wood panels

- Afterwards, it can be directly covered with many types of floor coverings.

- Lightweight, fire-resistant and sound-absorbing floor structure

- Very fast, light, and dry installation

- Possibility to insulate your low floor construction over the entire thickness.

- Spreading floor work over several days (no stress during installation)

- Circular floor construction with dry ecological & sustainable infill materials

Floor construction manual

- Place the StaenisGrid and adjust it to the correct height with a screwdriver. Use sawn wooden blocks under the Staenis feet to adjust it higher.

- Glue all legs to the substrate with PU foam; this way, the height adjustment remains correct after leveling.

- Pour the load-bearing leveling granules or aerated concrete into the grid and level them with a screed bar on top of the StaenisGrid.

- Place at least a 22 mm thick OSB board on this. Screw the wooden board into the slats of the StaenisGrid. Apply double boarding if necessary for extra strength.

- With a single sheathing on the load-bearing infill materials, the 22mm OSB will still flex slightly. With double sheathing (12mm + 18mm), the deflection is completely eliminated. (1 ton/m² compressive strength)

- Tip: Depending on the type of floor finish, you choose the thickness of the OSB. A thin floor finish requires a thicker OSB, while a thick floor finish can be combined with the minimum OSB thickness for this floor structure.

- Be vigilant: if the wooden joists flex when walked on, the subfloor may gradually sag under the weight of the installed StaenisGrid and the cellular concrete granules. It is recommended to first stabilize the subfloor and possibly opt for a lighter alternative, such as a non-tileable insulating screed.

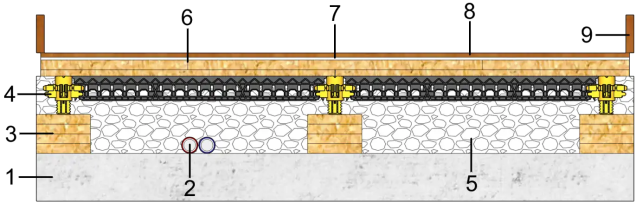

Side view of floor structure

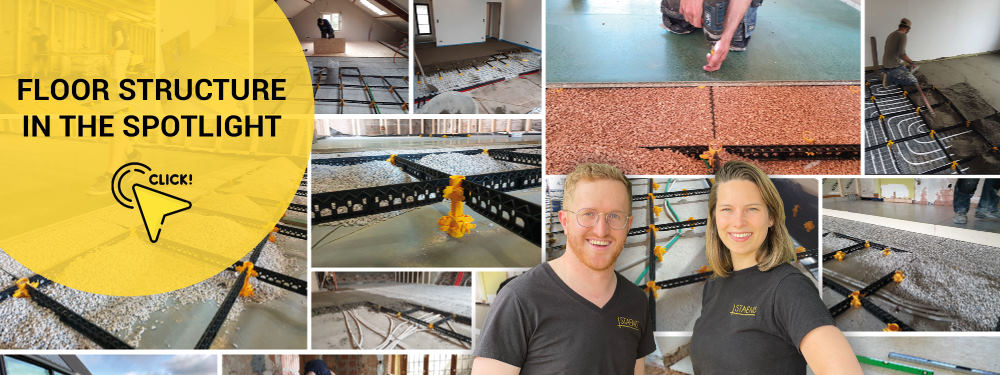

View this floor structure in real life via Sack Zelfbouw

Legend

- Concrete slab

- Pipes (heating, electricity, drainage, etc.)

- Wooden blocks 9 x 9 cm

- Staenis grid (thickness from 4.5 to 9 cm)

- Aerated concrete

- Double staggered OSB panel

- Subfloor / felt

- Floating floor covering

- Skirting board

Installation video

Placement of StaenisGrid

Placement of load-bearing dry filling materials

We deliver aerated concrete leveling granules in bags to your home

Aerated concrete leveling granules are a cheaper alternative to the standard leveling granules from, for example, Fermacell.

Cellular concrete leveling granules can only be installed in combination with the StaenisGrid, with an OSB board or Fermacell floor panel on top.

The cellular concrete leveling granules in bags are easy to transport and make it possible to level your floor dry by yourself.

The cellular concrete leveling granules are load-bearing, so you do not need to place 8 extra supports per square meter.