CircoFloor manual

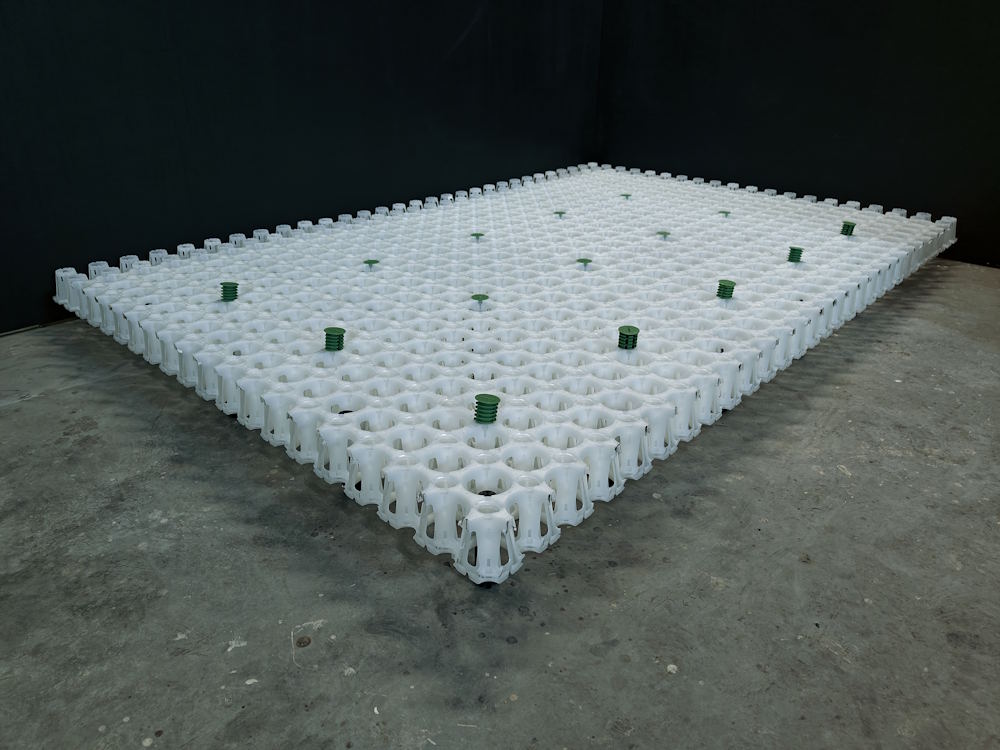

Welcome to the manual for the CircoFloor system. In this photo guide, we will guide you step by step through the installation of the CircoFloor dry floor system, so that you can efficiently and with high quality create a durable floor.

The CircoFloor system is largely assembled on a workbench, allowing you to work comfortably without straining your back.

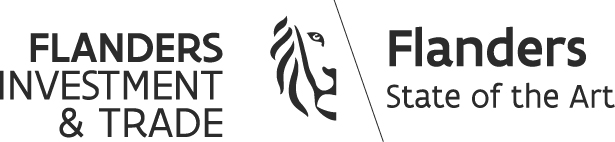

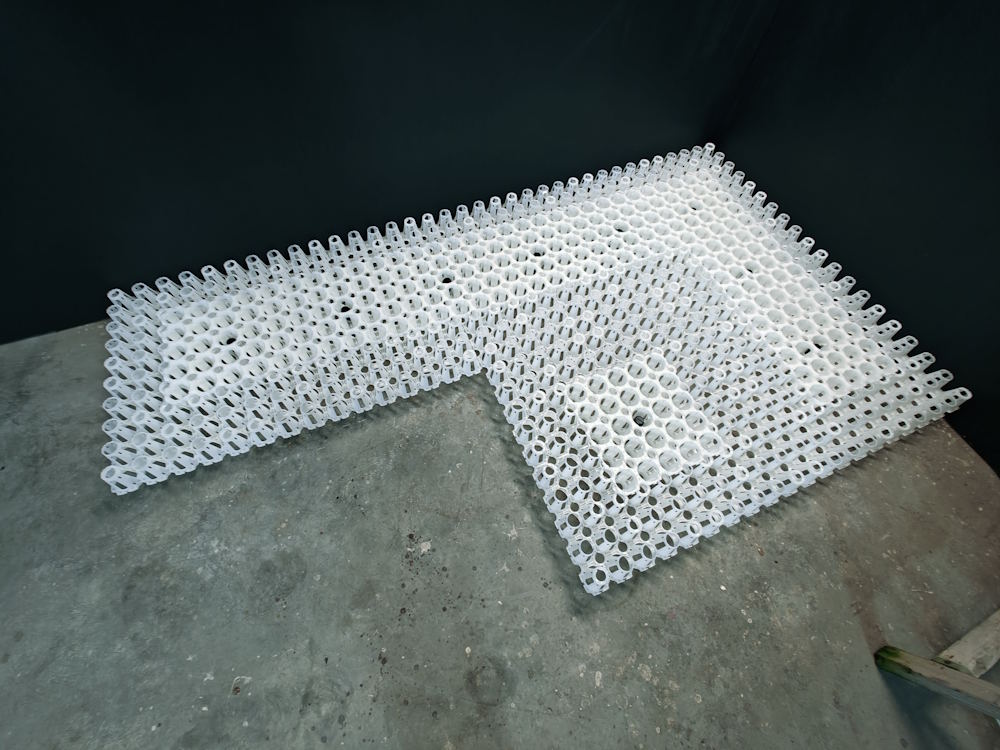

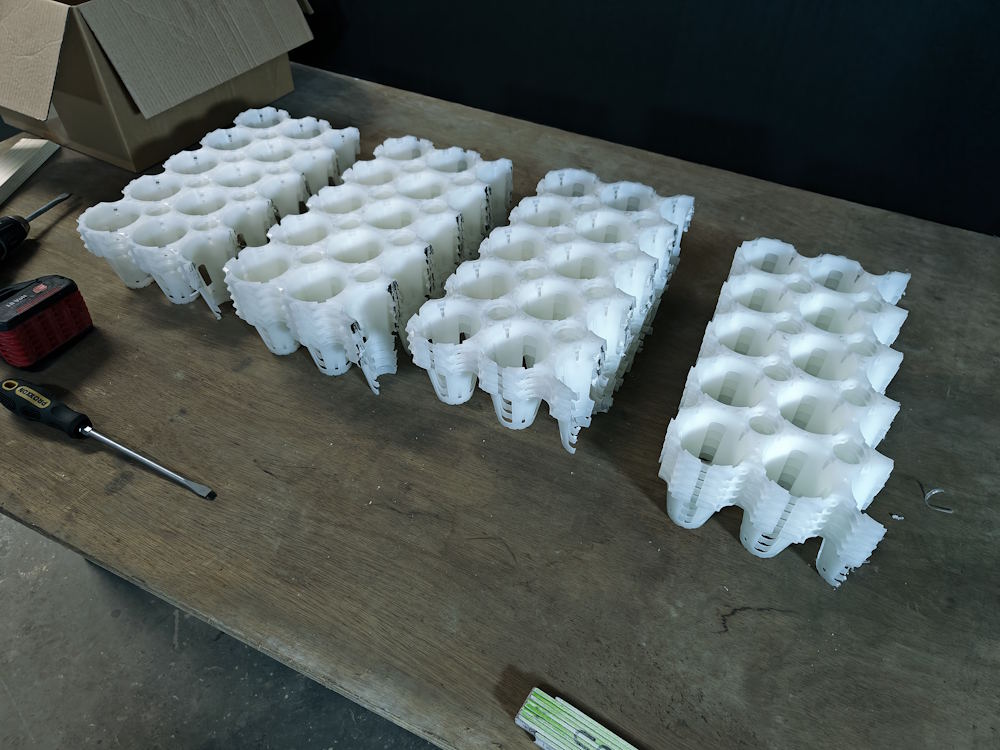

Start by placing the first structural panel on the table.

Take the second structural plate and click it sideways into the first structure so that they are firmly connected.

Pay attention to the installation direction; make sure that all structures are placed in the same direction for correct assembly.

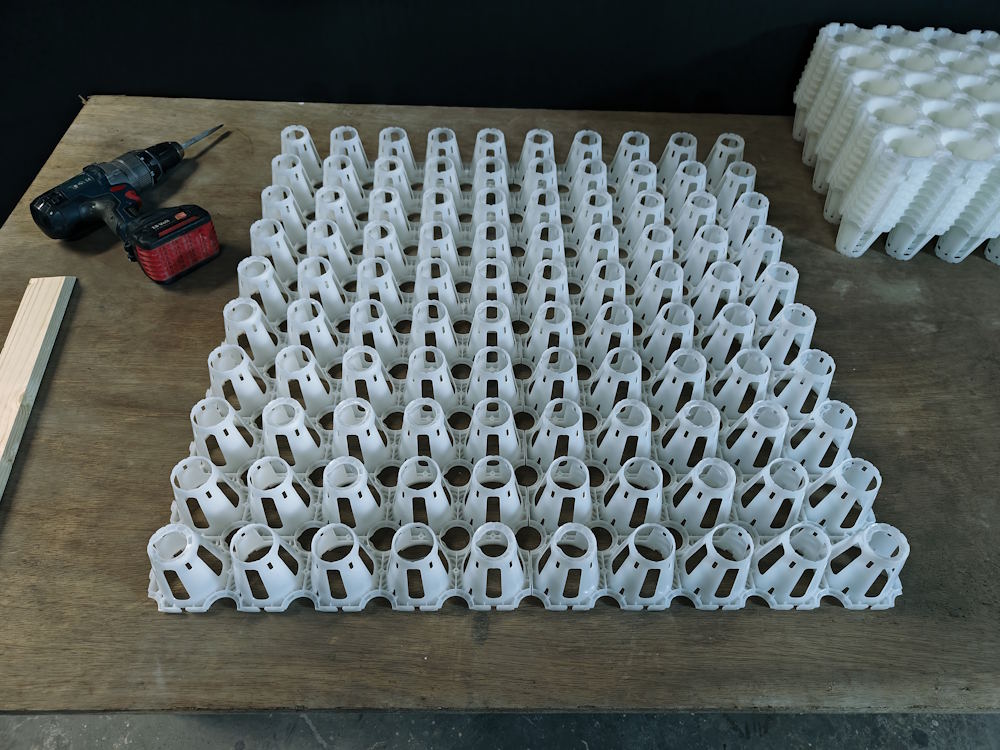

Add the third structural panel to the assembly.

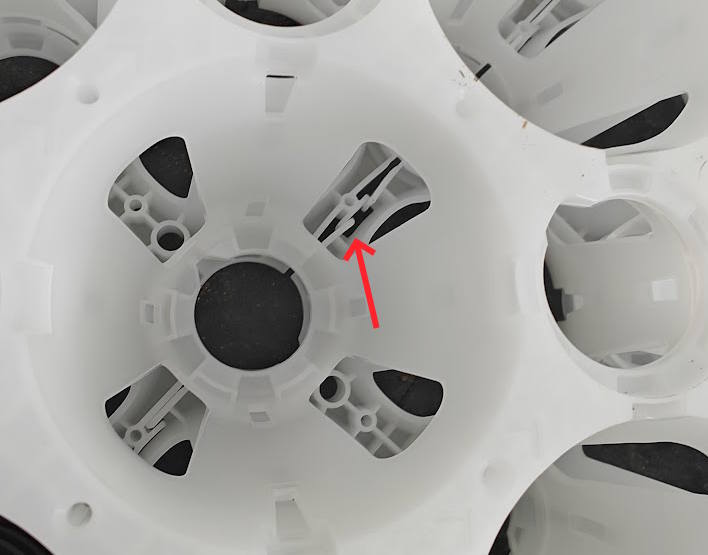

Check the direction on the inside of the structure; the arrow-shaped ribs indicate the correct placement direction.

Arrows at the top also indicate the correct direction.

Place the fourth structural panel on the table and connect it to the previous panels.

The correct direction is crucial to ensure that the thread matches and the set screw fits properly.

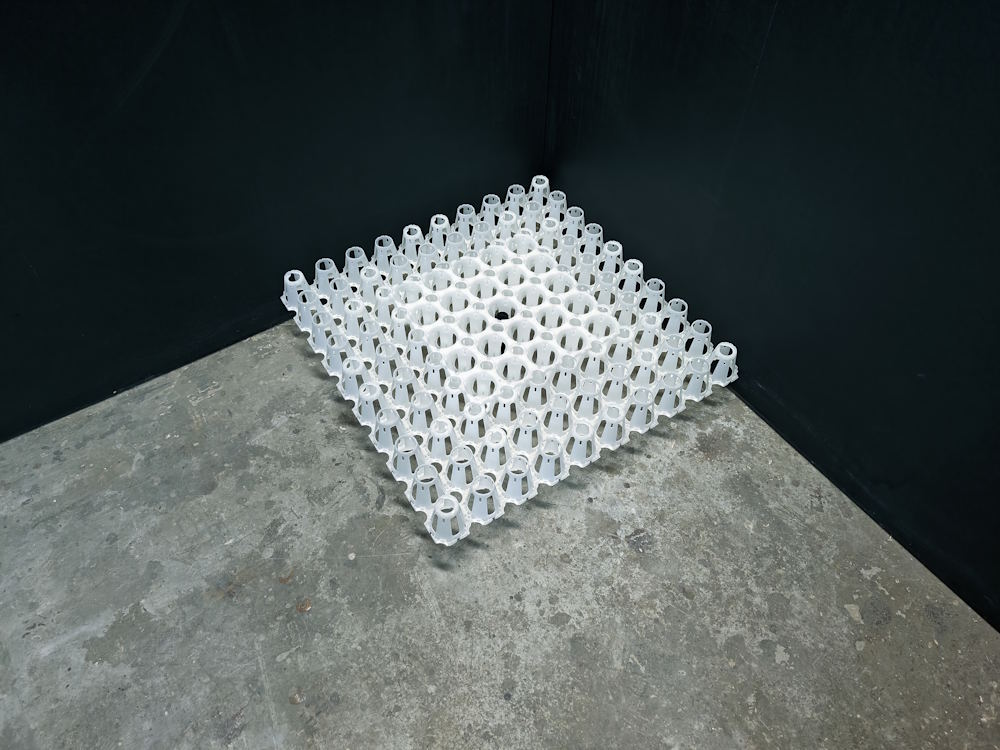

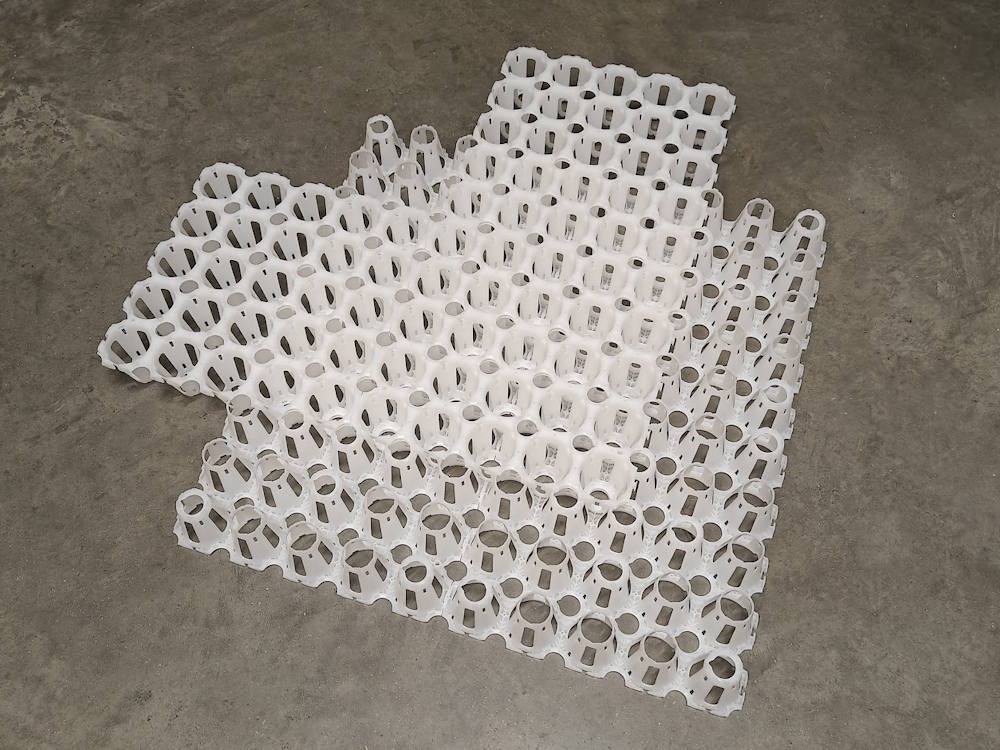

Place a structural panel upside down and in the same direction in the middle and click it onto the four surrounding structural panels.

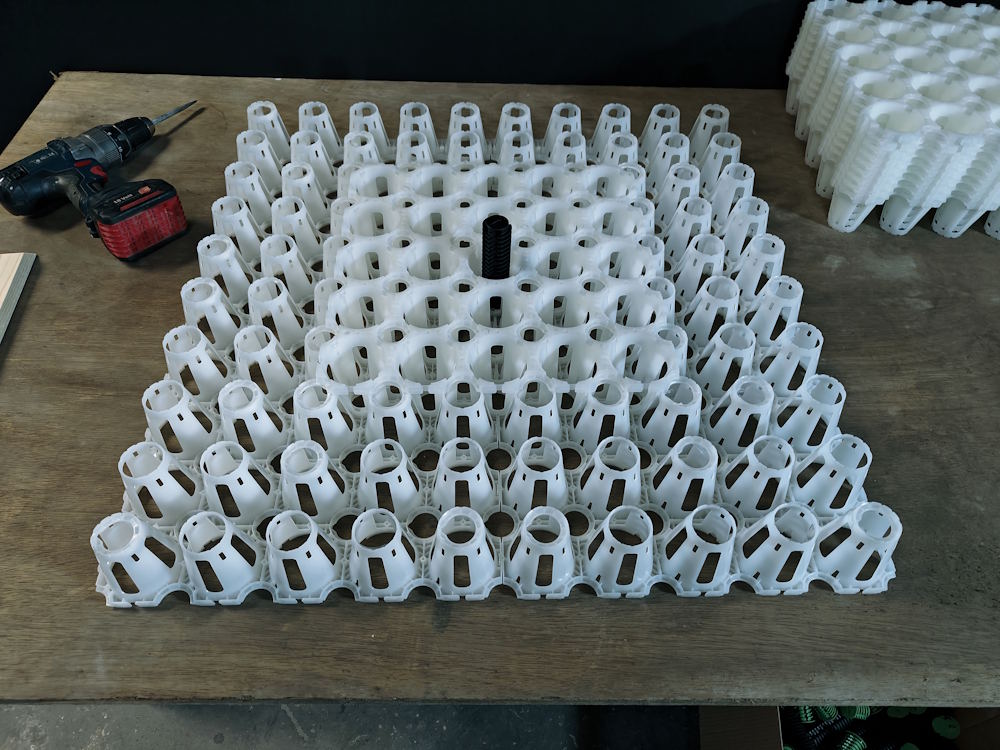

Tip: To work even faster and more easily, mount several pieces next to each other on the table.

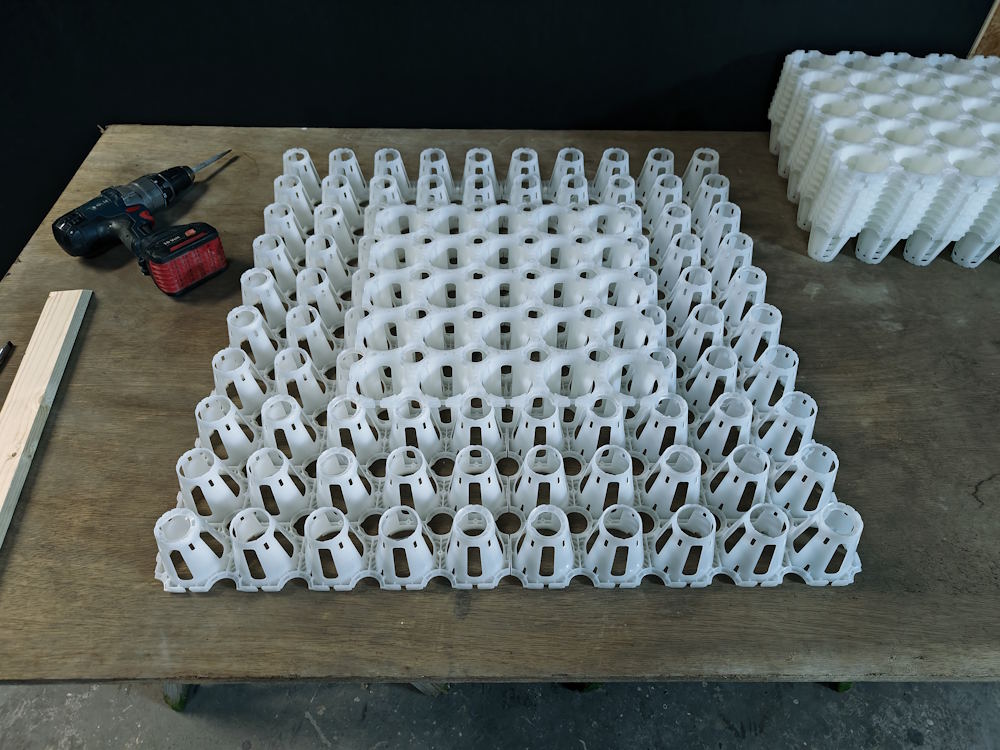

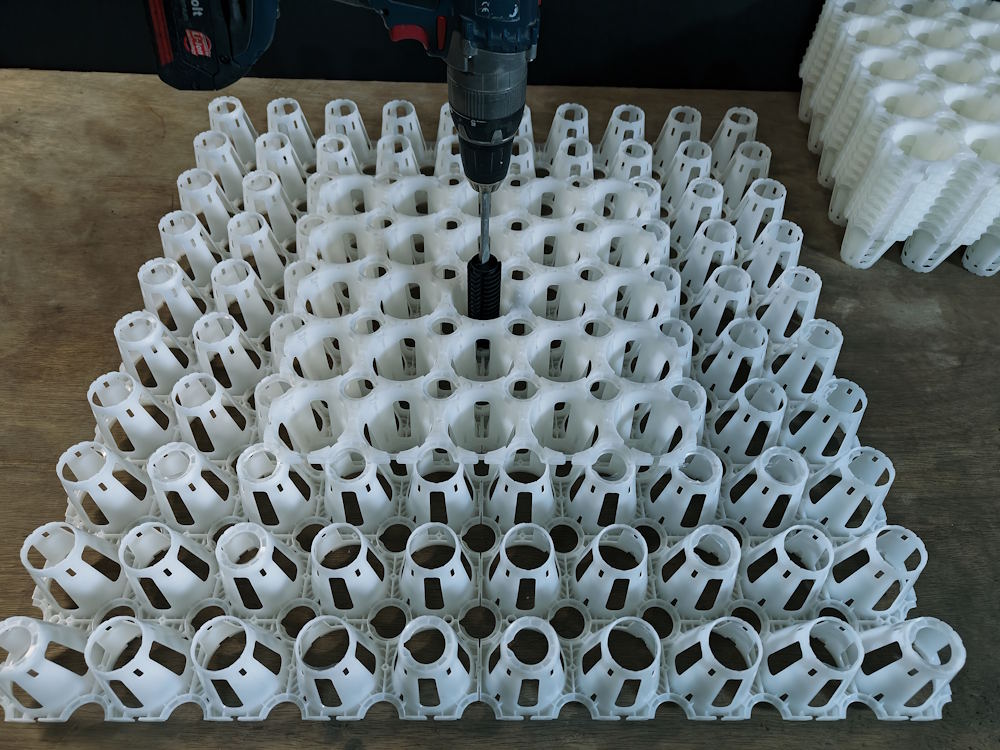

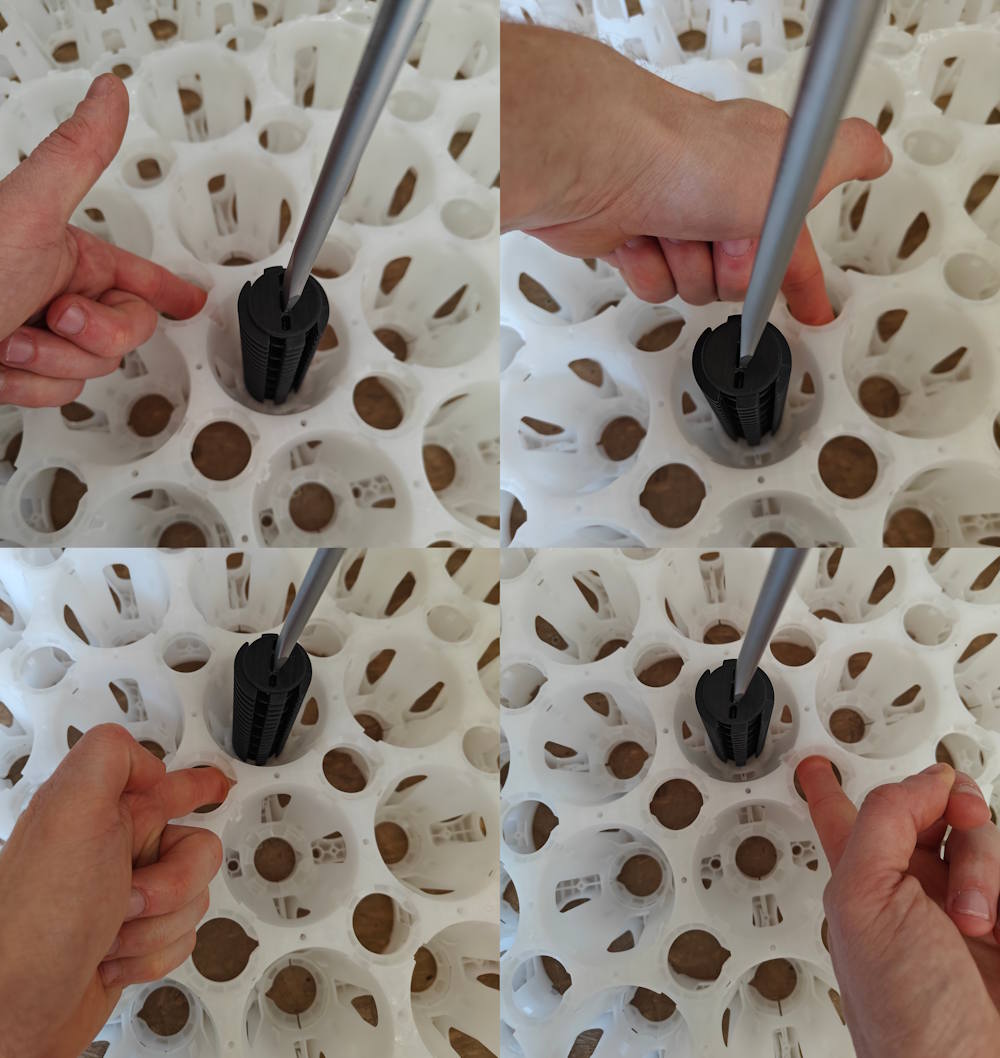

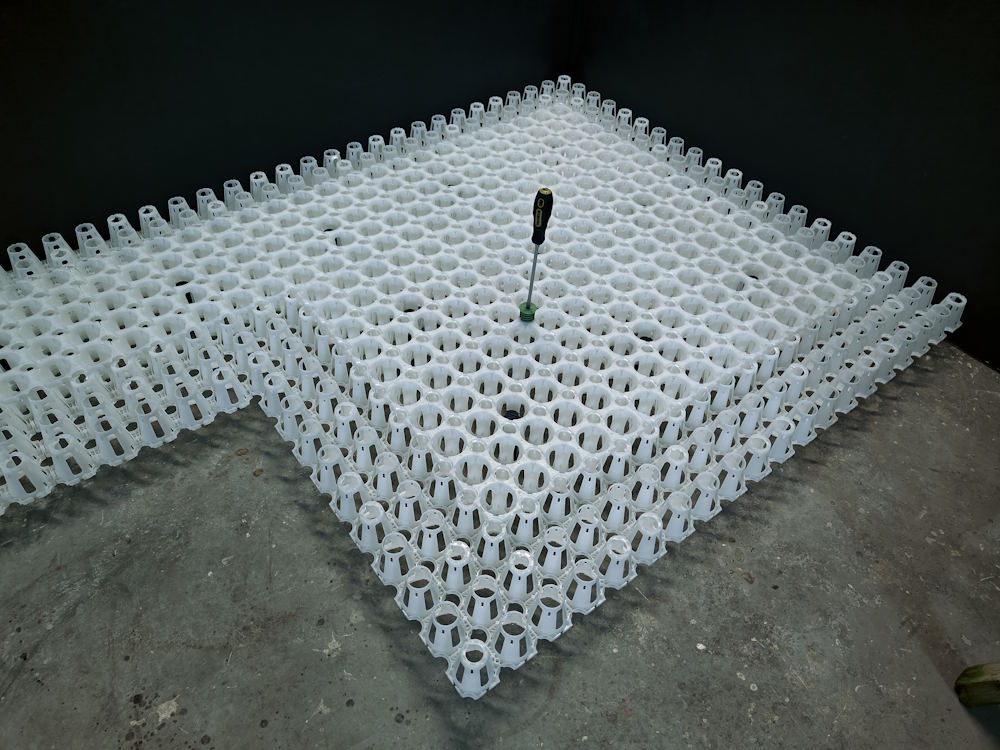

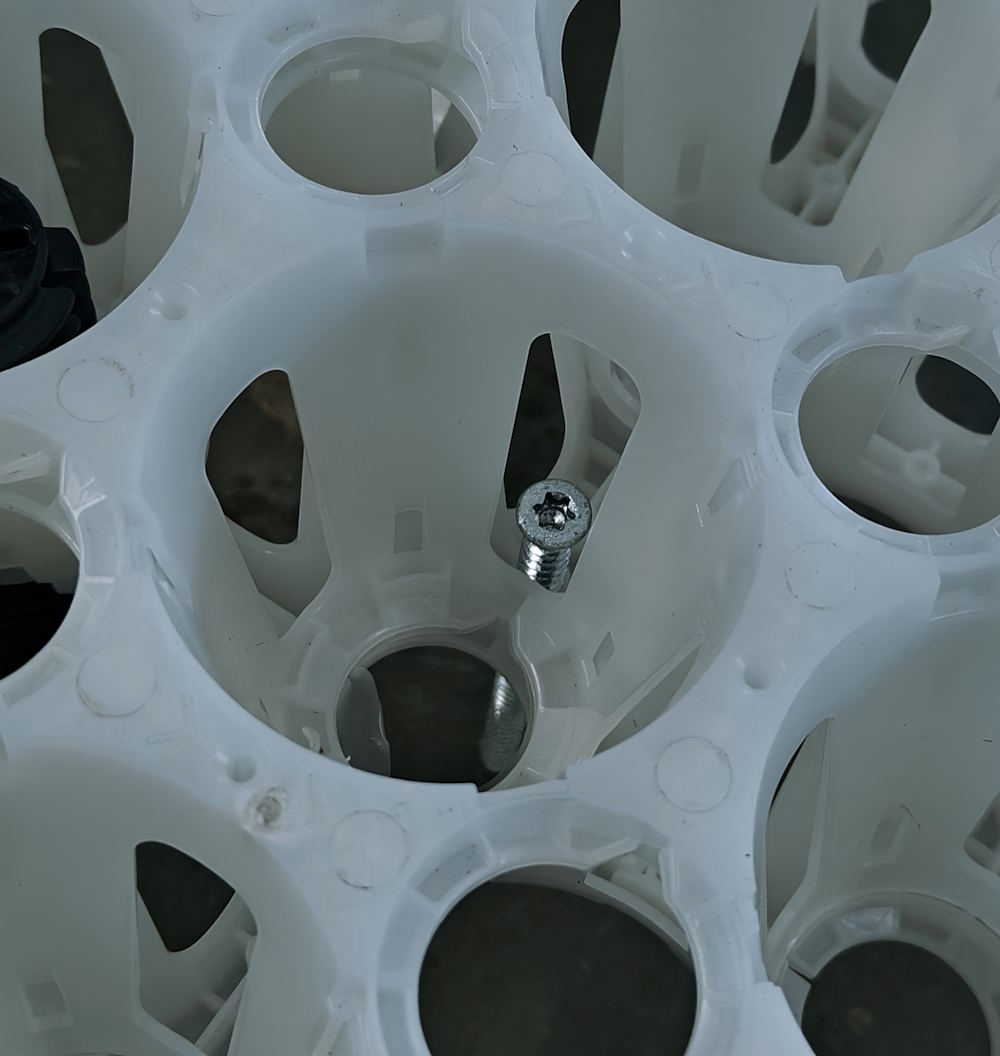

Place an adjustment screw in the center to connect the four lower structural plates to the upper one.

Although a flat screwdriver suffices, it goes faster with a power screwdriver. Tip: grind down a flat screwdriver to use as a bit in the power screwdriver.

Adjust the adjustment screw to the desired height.

This saves time during installation.

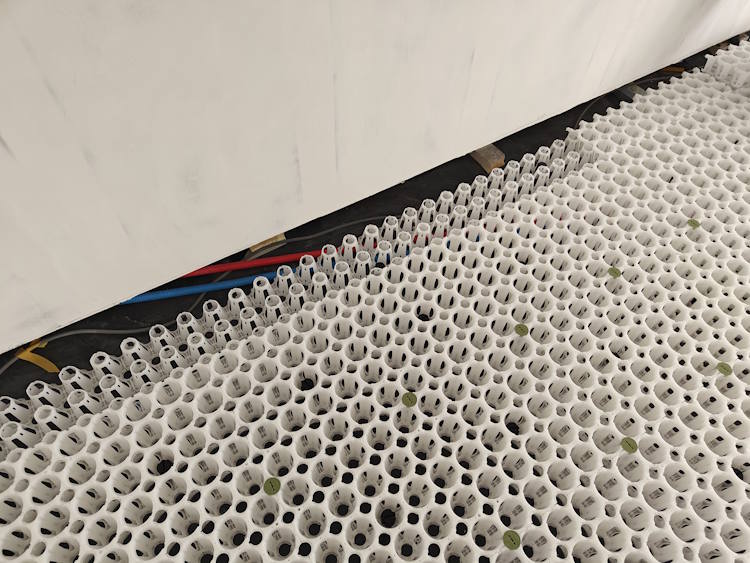

Place the first composite part on the substrate.

Building components such as floors that come into contact with the ground must be permanently protected against rising damp. A PE film (0.2 mm) must be used to prevent the dry construction of the subfloor from becoming moist. To this end, the film is applied over the entire substrate. Care must be taken to ensure that the strips overlap by at least 20 cm. Along the edge, the PE film must be brought up to the level of the finished floor.

If the floor contains residual moisture, a PE foil (0.2 mm) must be used to prevent moisture from rising into the dry construction of the subfloor. For this purpose, the foil should be applied over the entire substrate. Care must be taken to ensure that the strips overlap each other by at least 20 cm. Along the edge, the PE foil must be brought up to the level of the finished floor. If the building component contains no residual moisture, the PE foil may be omitted in the case of a solid intermediate floor.

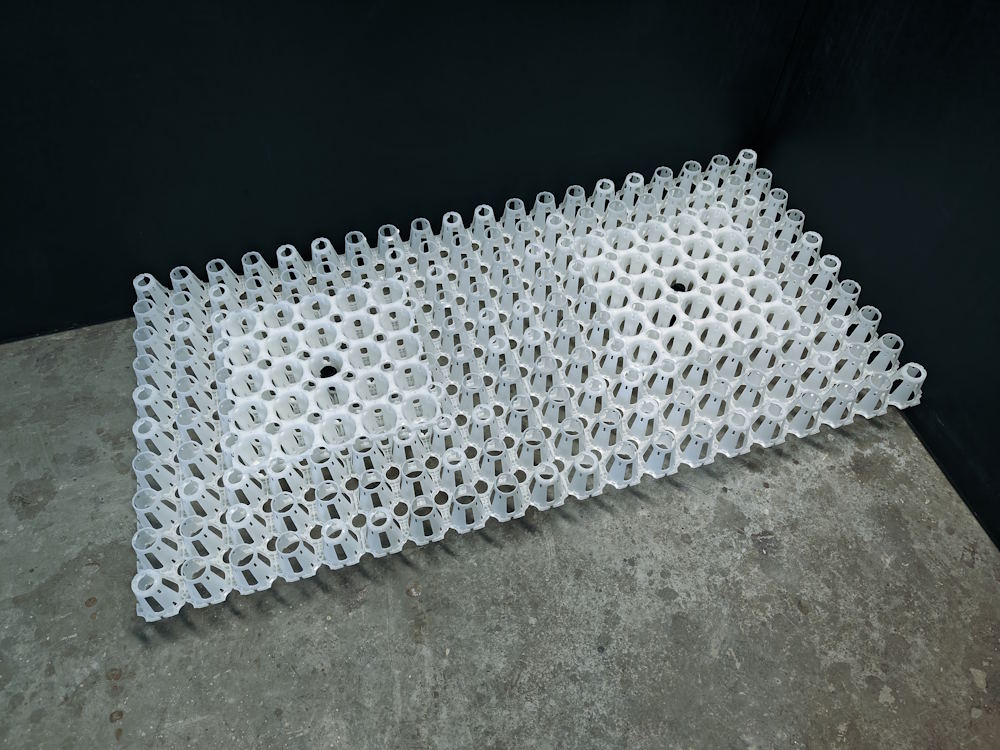

Create a second assembly and connect it laterally to the first part.

Still pay attention to the orientation of the structural panels during installation.

Determine the correct height of the CircoFloor system using a reference point.

Use a wooden slat with a pencil line to easily adjust the system to the correct height.

Now also make sure that both assemblies are adjusted to the correct height.

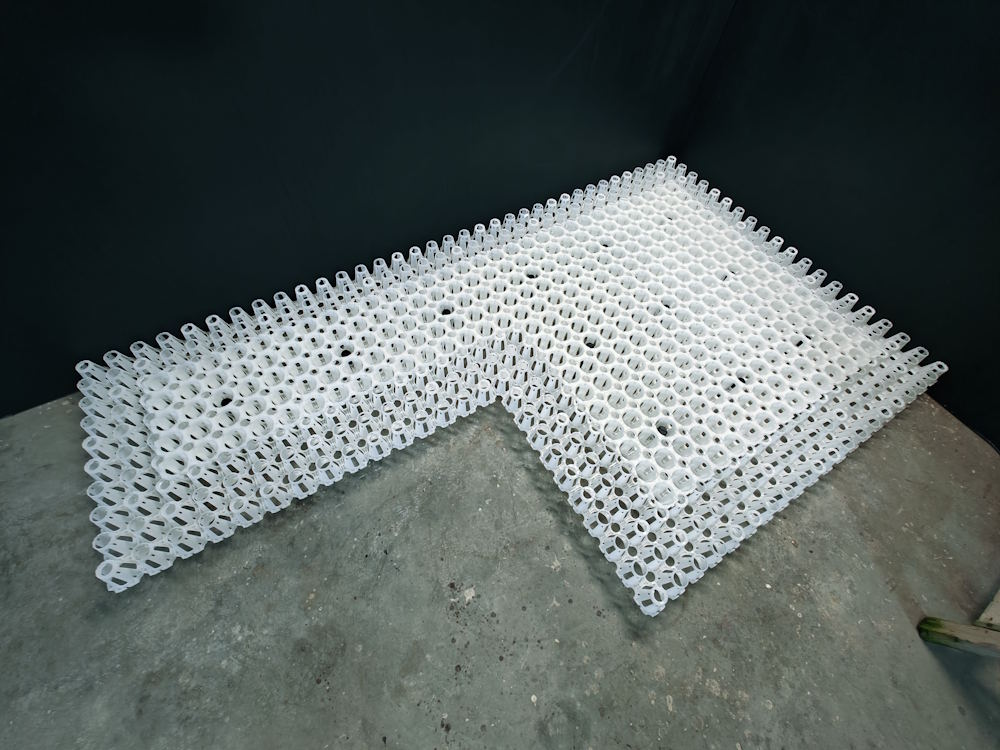

Connect the two assemblies by placing an additional structural panel between them (without clicking them together).

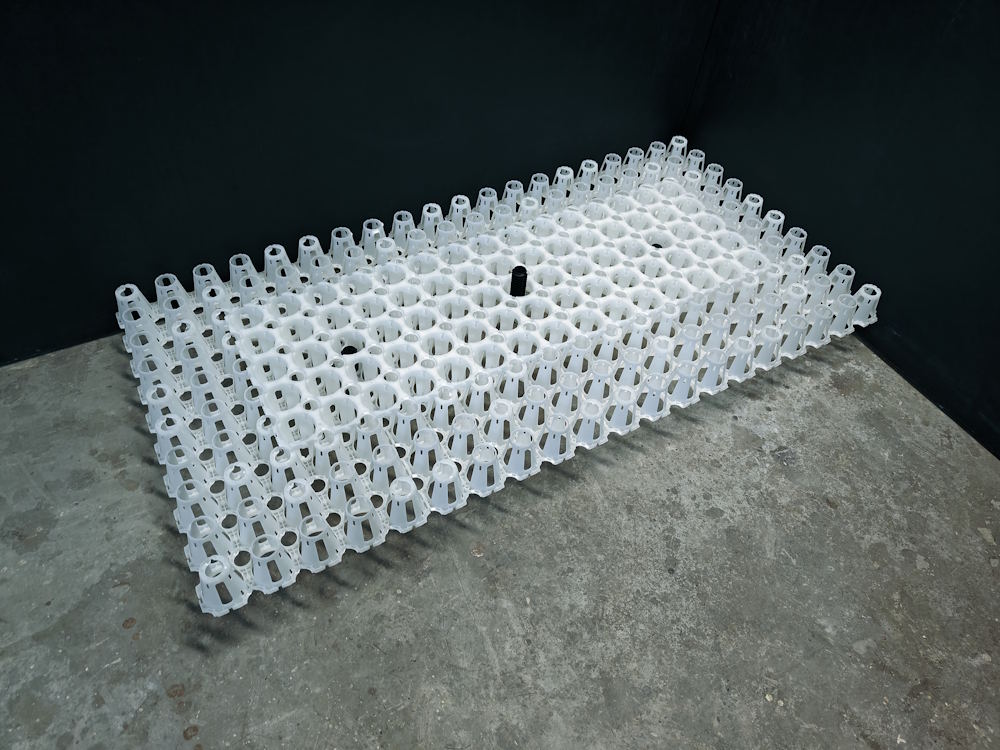

Insert the extra structural plate slightly deeper into the other inverted structural plates, without pushing them away.

Screw the black adjustment screw into the center of the extra structure plate (with 4 converging corners at the bottom) and let the thread engage the upper structure and the lower structures.

It helps to manually push the structural plates together while screwing through the threaded holes.

It is important that the structures are drawn towards each other when the adjustment screw is screwed in. This way, everything clicks together and the structures form a strong whole.

Check at each adjustment screw that all structures fit together properly. If necessary, loosen the screw and try again.

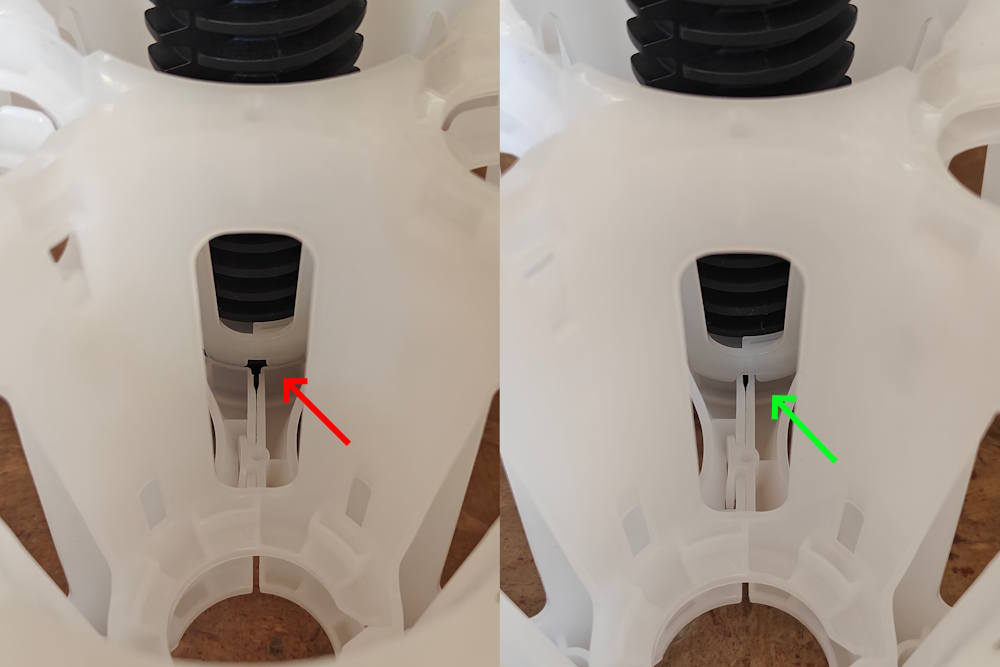

Make sure that the side click systems always fit together neatly and not as shown in the photo.

Make sure that the top and receiving side always hook neatly into each other and not as shown in the photo.

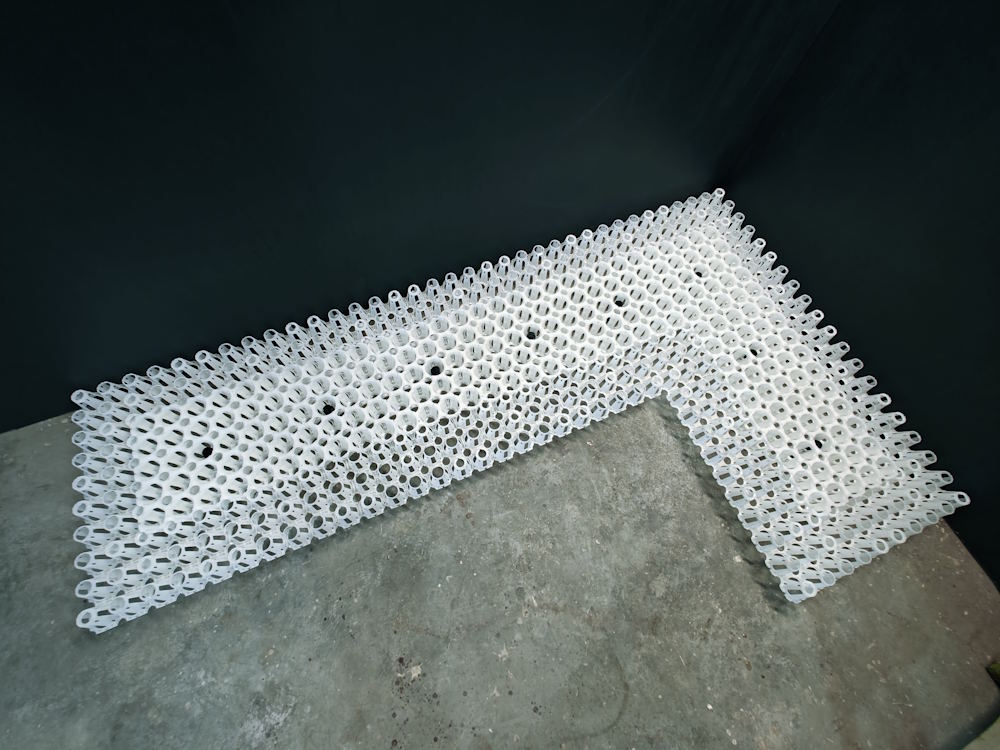

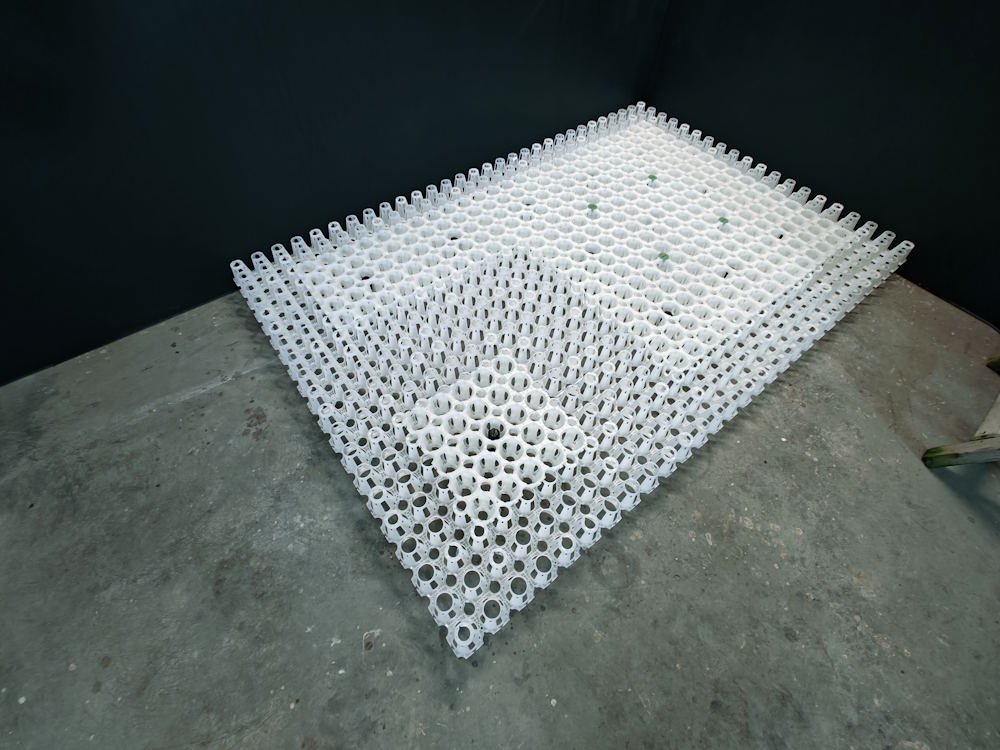

Expand the system further. As soon as an L-shape is formed, the whole becomes more stable.

Continue building the CircoFloor system according to the area you want to cover.

It helps to connect the connected structures together in advance.

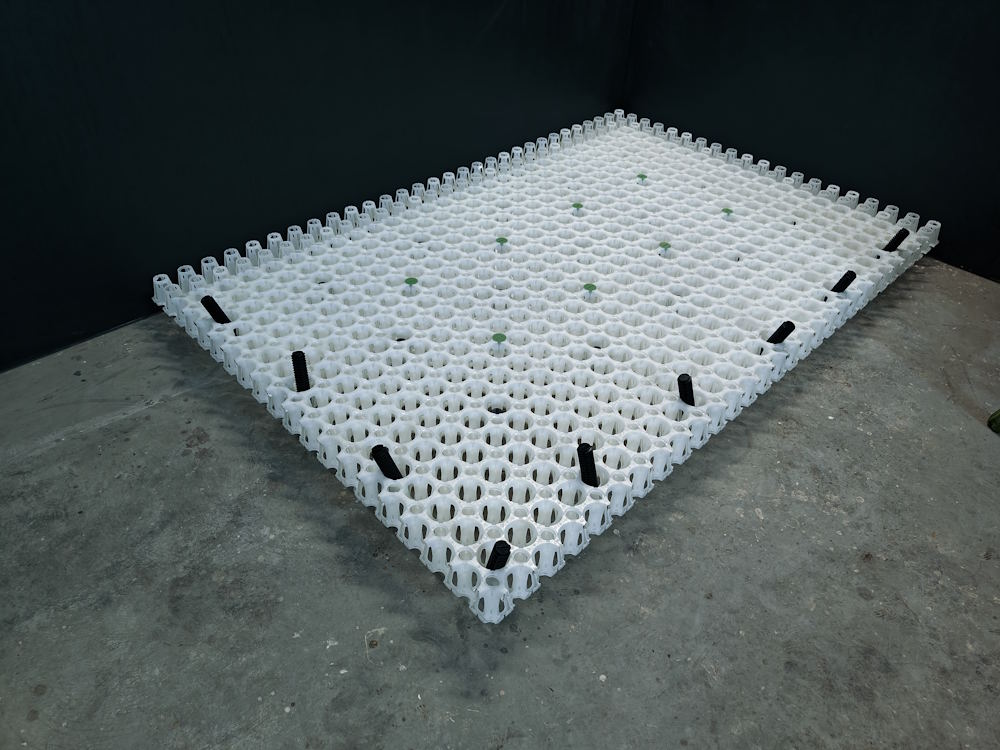

Place the structural plates back on top and secure the whole assembly with set screws for extra stability.

Now place the green locking screws to firmly connect the top four structural panels to the underlying structural panel.

Continue building the system until the entire floor area is covered.

Use a grinder with a metal cutting disc to easily cut the system to size at the top and bottom.

By stacking multiple systems on top of each other and using a larger cutting disc, you can cut multiple structures to length at the same time.

Finish the edges of the system with the custom-cut pieces.

Depending on the top layer, you can fit precisely or somewhat less precisely against the wall.

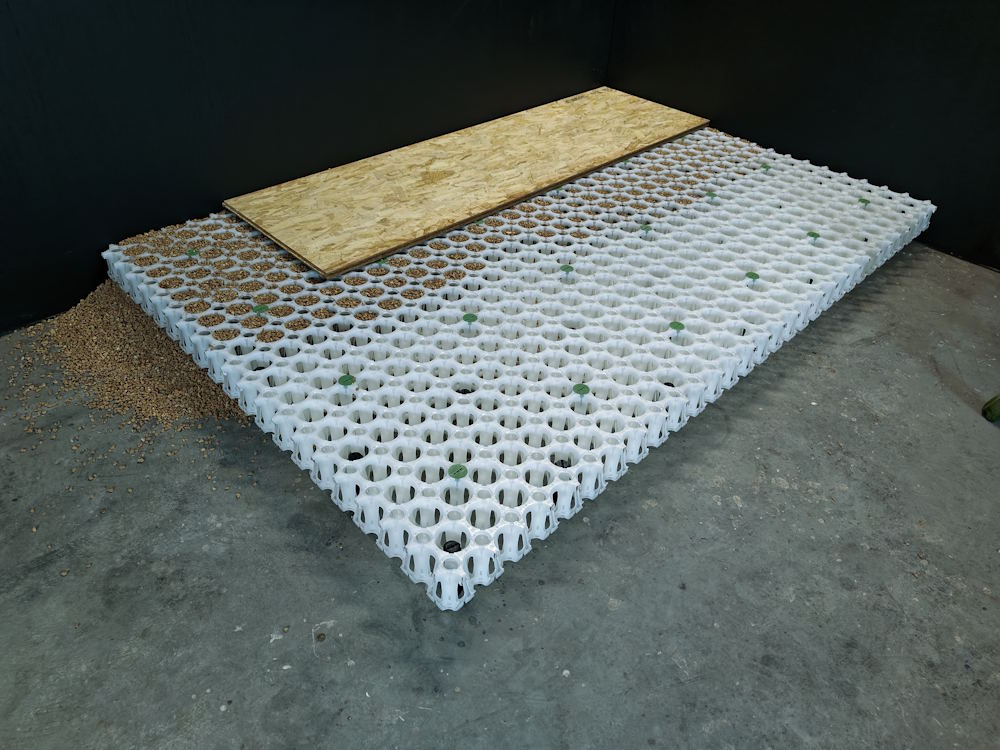

When using a thicker OSB board on the structural boards, it is acceptable to stay a few centimeters away from the edge.

Always pay attention to the direction of the cut pieces, as this is important so that you can use the double thread afterwards.

Place set screws in the threaded holes near the wall for extra support.

Preferably choose holes with double threading for extra load-bearing capacity.

Screw the remaining green fastening screws into the structural panels for a solid construction.

In addition to each black adjustment screw, you can attach up to four frame screws to the surface.

Wooden base: pre-drilling is not necessary. Place one frame screw every 1 m² for extra stability.

Concrete surface: first drill a hole Ø 6 mm through the existing hole in the structural plate and then screw in the frame screw. Always insert at least a few frame screws to fix the system.

Do not over-tighten the screw; once it is firmly in the substrate, the system is secured. Thanks to the thread in the structural plate, you do not have to turn the screw all the way down; once it is firmly in the substrate, the system is secured.

Multi-layer parquet can be glued to OSB 3/4 plating, provided that the CircoFloor system is anchored to the substrate with at least four frame screws per m² and the OSB 3/4 plating is attached to the CircoFloor system with at least 13 wood screws per m².

To be able to glue tiles onto CircoFloor, the surface may only deflect minimally under a certain point load.

Therefore, it is important, when tiling, to place one extra black adjustment screw next to each green adjustment screw.

Even with floating floor coverings, the additional adjustment screws limit deflection, although this is not necessary.

In future versions, the structure will be made of fiber-reinforced plastic, making these 7 additional adjustment screws unnecessary.

The system is now perfectly level and is firmly attached to the substrate.

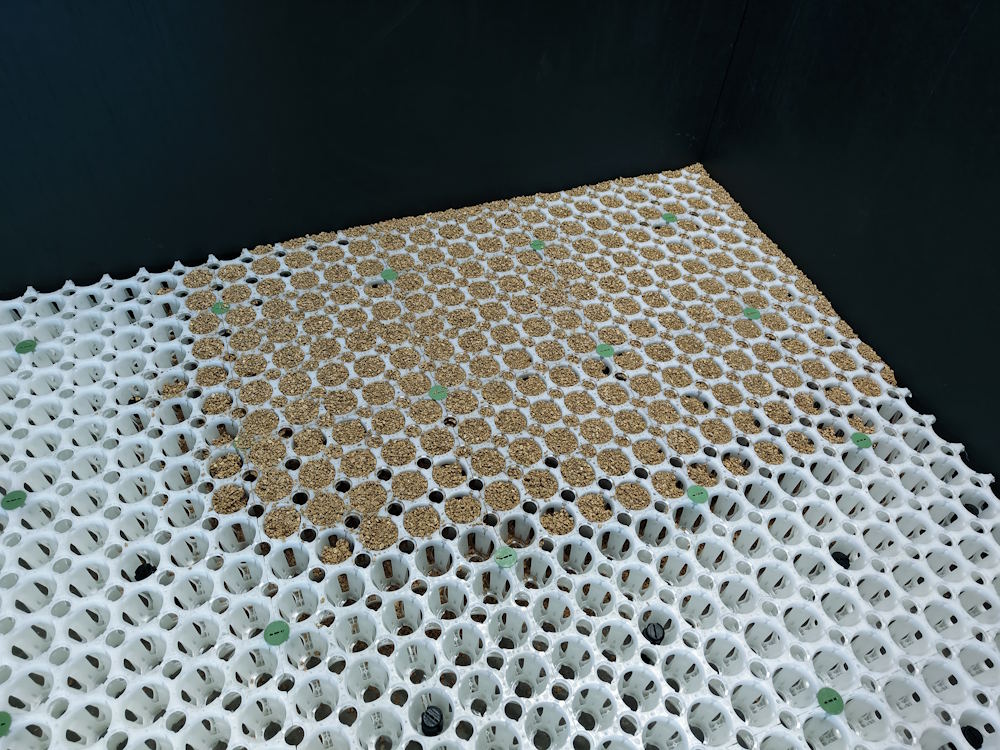

You can now fill the CircoFloor system with insulation material in the form of loose granules.

Use a brush or a slat to evenly distribute the granules until the system is completely filled, including the spaces underneath.

You will now notice that the sound of footsteps is greatly dampened and the floor feels of high quality.

You can easily press down the loose insulation with a separate structure plate.

After the system is insulated, you can panel it and finish it as desired.

Screw OSB boards onto the flat parts of the system. Use the structural boards as a template to determine where to screw.

Always use screws with a diameter of 4.5 mm, which have a thread over the entire length, without a flat shaft, for optimum grip.

Place 3 screws across the width of the OSB board and this every +- 40 cm. Placing 13 screws per m² is recommended.

One screw with a diameter of 4.5 mm has a maximum pull-out force of 40 kg.

You can also create a template yourself that perfectly shows where you can screw.

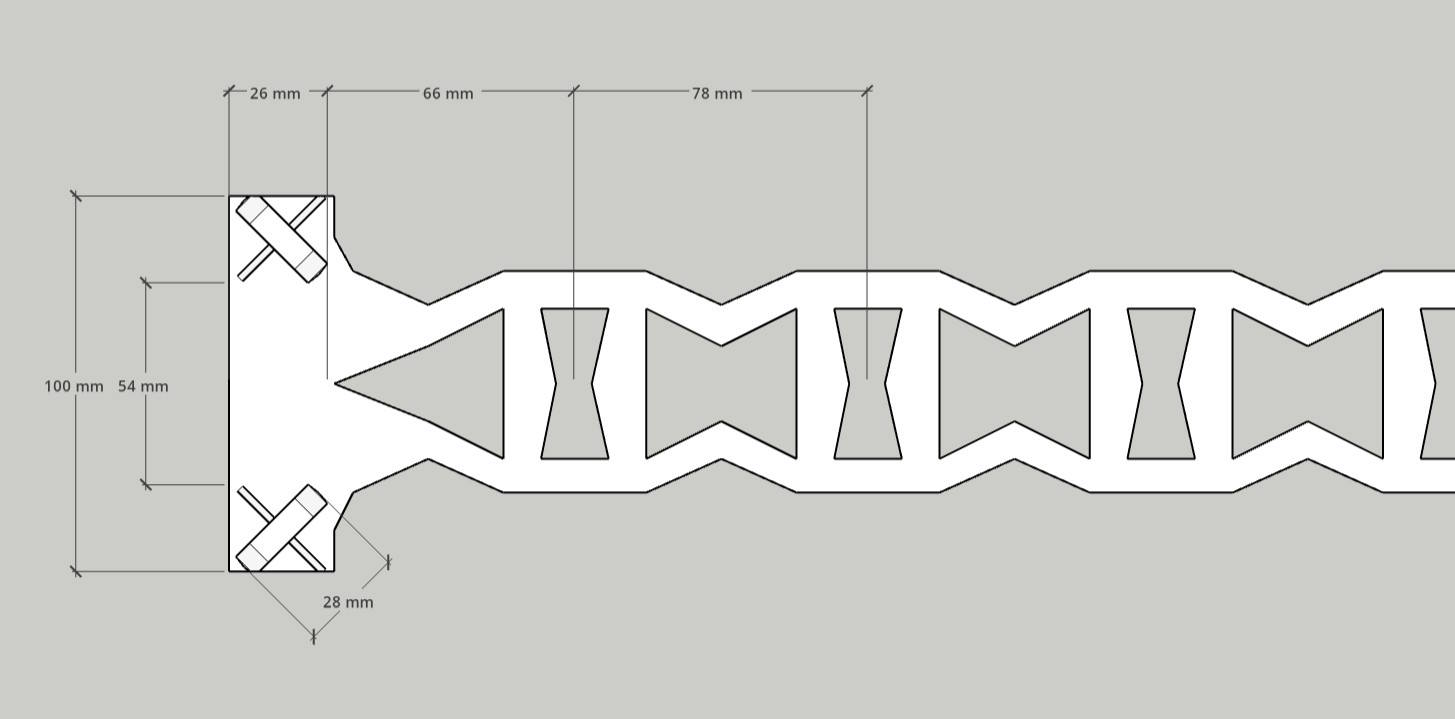

Here you can see a drawing with dimensions.

This plastic mold is also available for purchase in our webshop with the CircoFloor products.

This greatly simplifies screwing the OSB to the CircoFloor system.

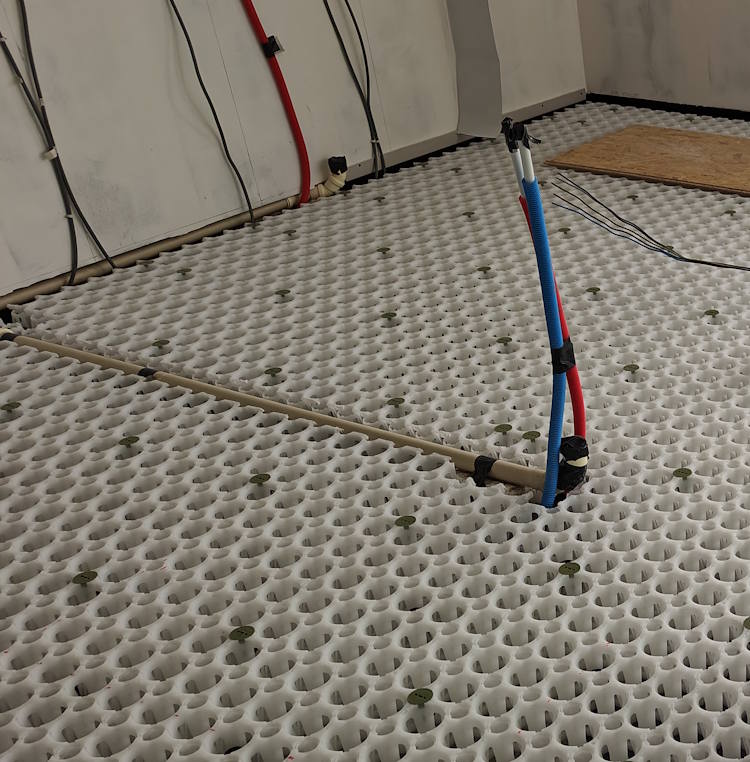

You can place utility lines under the system, which remain accessible by partially and locally unclipping or unscrewing the system.

If there is not enough height, consider the pipe as a wall and work around it with the CircoFloor system.

This is how to install the CircoFloor system efficiently and to a high standard.

Contact

Do you also want to make a positive impact and contribute to a more sustainable future?

Then contact us! Together we will create the perfect flooring solution for your project and make a difference.

Request a quote