Specifications CircoFloor

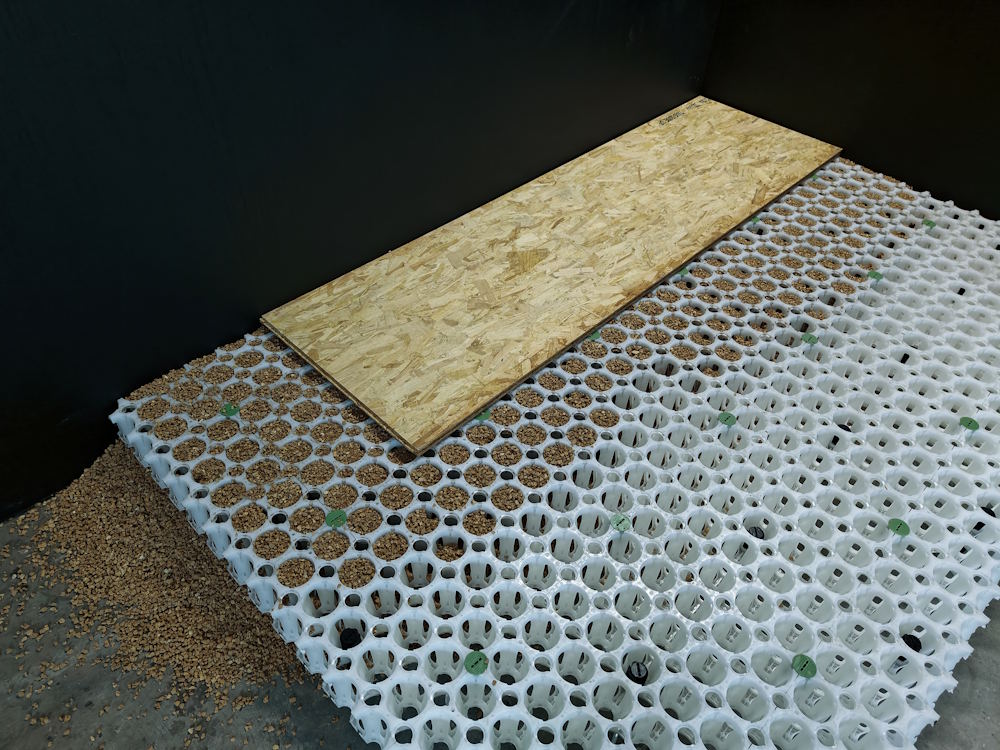

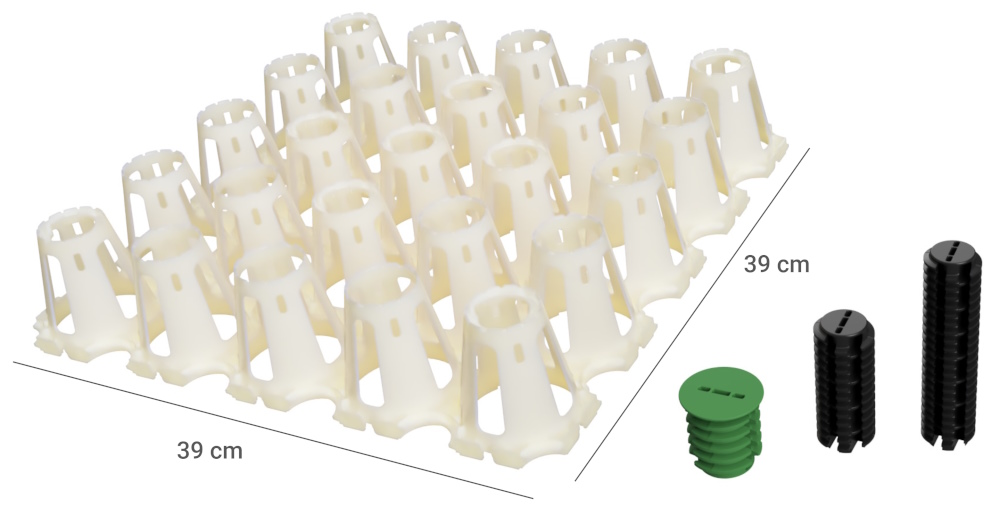

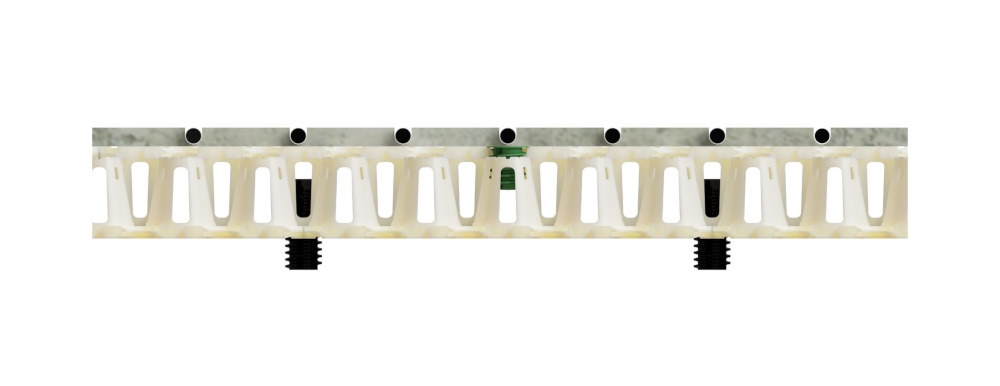

The CircoFloor system consists of a structural plate, two types of adjustment screws, and a locking screw.

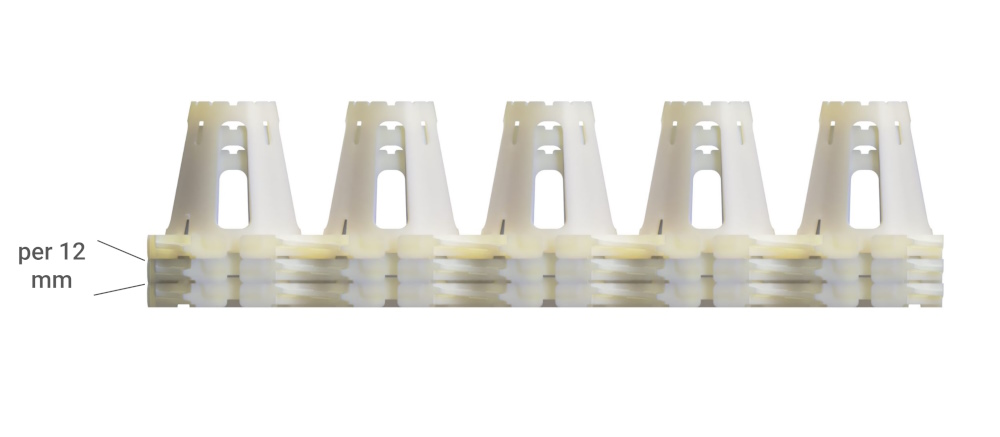

The structural panels are clicked together to achieve the same effect as two overlapping OSB panels. This creates a rigid structure.

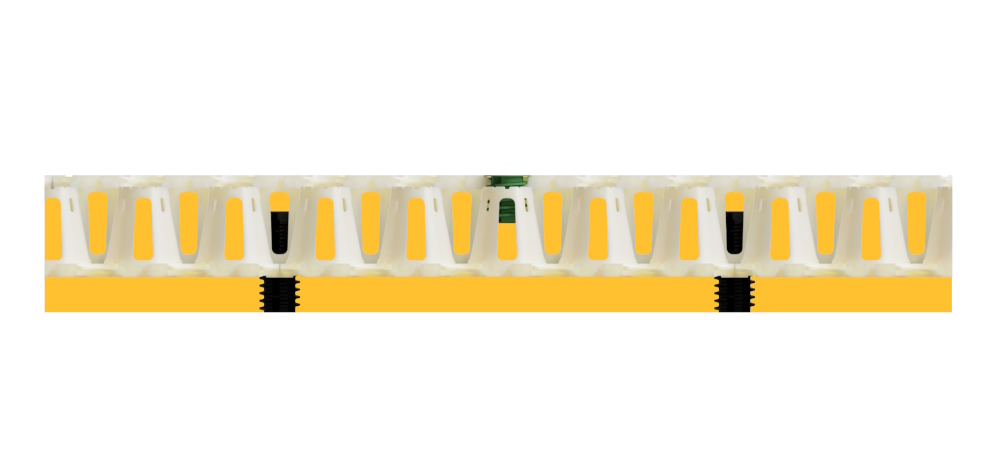

With the black adjustment screws, the installed structural panels at the bottom can be secured and adjusted in height, both during and after installation.

The green locking screw ensures that the top structural panels are firmly secured, keeping everything neatly in place.

Thanks to the double thread with minimal play, the rough substrate and – if applied – the filler, the screws remain perfectly in place.

The system is made entirely of polypropylene (PP) plastic, 5% of which consists of recycled material. Since a floor is typically replaced every 25 years, CircoFloor can be reused each time and therefore lasts for centuries. This makes plastic the ideal moisture-resistant material for this application.

The structural panels measure 39 x 39 cm and have a height of 7.8 cm.

The smallest adjustment screw is 8.7 cm high, while the largest adjustment screw has a height of 14.7 cm.

The green fixing screw is 4.2 cm high and is used exclusively for securing the structural panels.

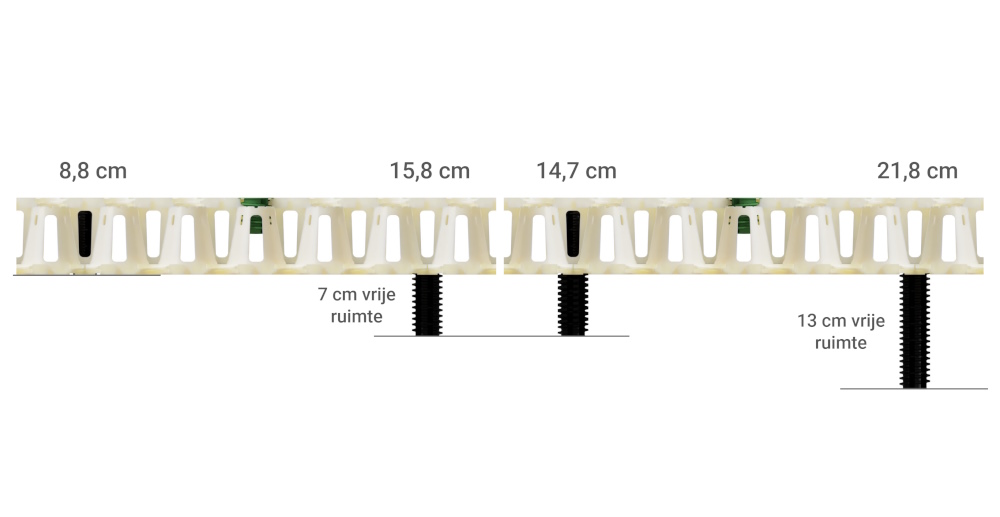

The interlocked structural panels have a height of 8.8 cm.

With the smallest adjustment screw, a height of up to 15.8 cm can be reached.

With the largest adjustment screw, a height between 14.7 cm and 21.8 cm can be achieved.

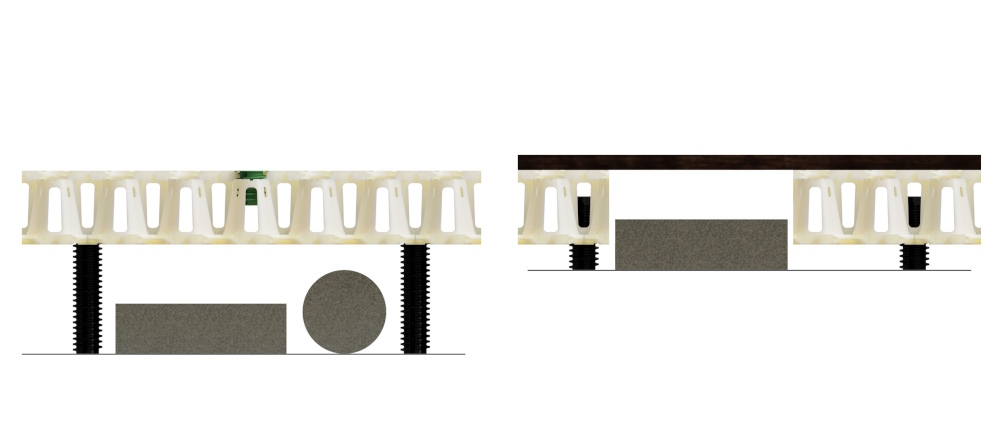

The system is ideally placed above utilities. Prior to installation, the required height for the CircoFloor system is therefore taken into account.

Due to the panels on top of the CircoFloor system, parts can also be omitted to allow utilities to pass through.

OSB boards can be installed bridging, unlike Fermacell or Knauf Brio boards. Therefore, it is sometimes necessary to first install an 18 mm OSB board, on which a Fermacell or Knauf Brio board is then placed.

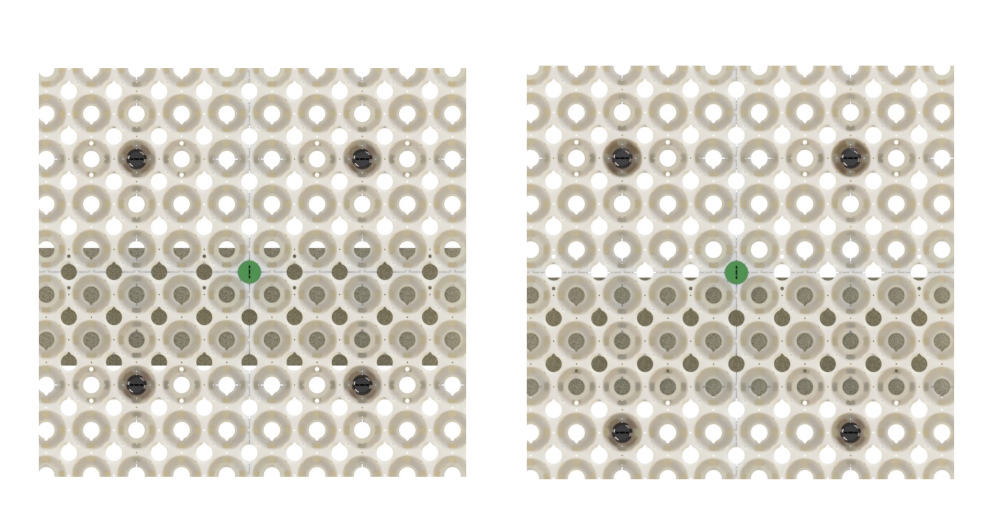

Thanks to the many threaded holes, an adjustment screw can easily be moved so that it does not end up on top of utilities.

This provides a flexible installation that takes into account the existing infrastructure.

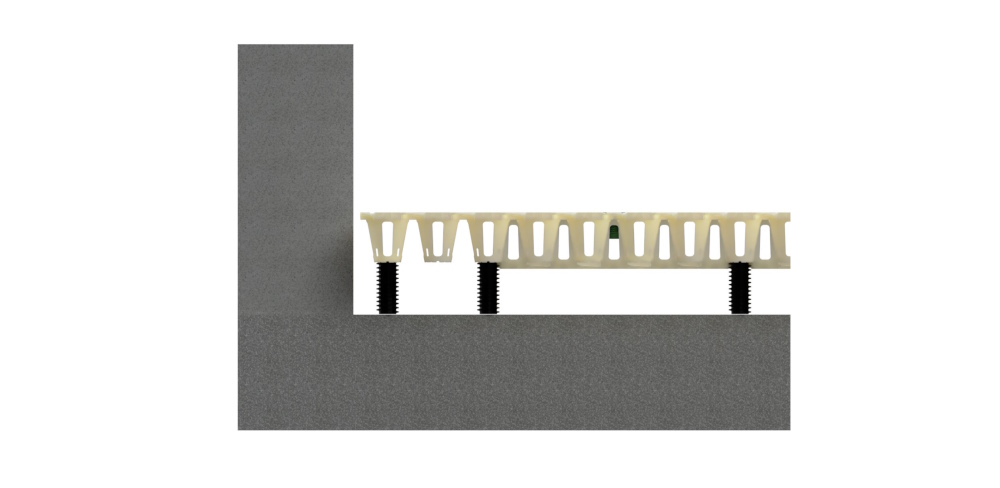

Thanks to the double structure, it is easy to have the system seamlessly connect to the walls.

The connection between two clicked together structures, fixed with adjustment and locking screws, can withstand a distributed tensile force of up to 875 kg/m².

A single structure can be chosen to connect to the walls, which results in less labor and material.

Or a double structure can be chosen for the walls, which achieves the full load-bearing capacity.

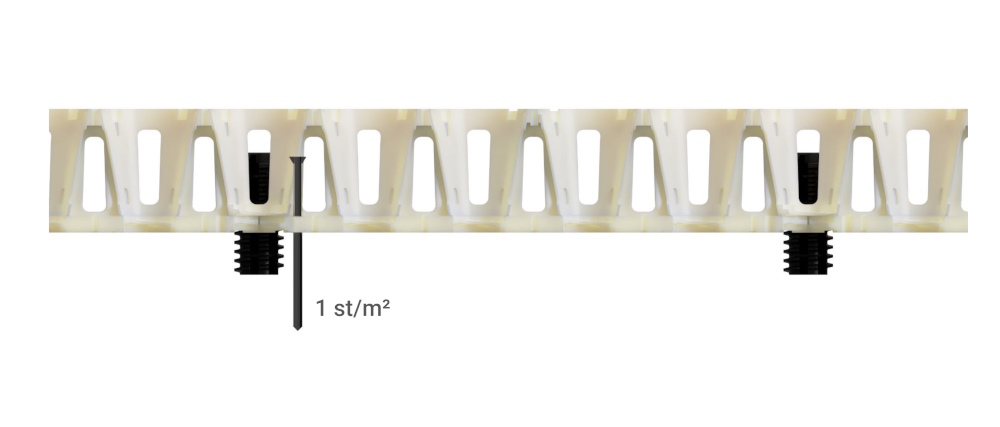

The floor construction system is fixed to the substrate using frame screws.

Because of the thread in the structural plate, you don't have to screw the screw all the way down and the system is secured as soon as the screw is anchored in the substrate.

Per m², 1 frame screw is installed, and if necessary, more can be installed per m².

One frame screw anchors the CircoFloor system to the substrate with a maximum pull-out force of 145 kg.

The cup-shaped structural plates transfer the load from one 'cup' to another.

As a result, the load loses strength and the sound is muffled, all with a lightweight system.

Once the system is stably installed and finished with paneling or floor covering, the whole functions completely noiselessly.

Acoustic tests still need to be carried out.

Loose insulation granules can be scattered through all the holes and under the system.

Cavity wall insulation can also be injected after the structural boards have been installed, without gluing.

Some commonly used cavity wall insulation materials are mineral wool, such as glass wool or rock wool, cork granules, insulation chips, cellulose, wood wool, and EPS beads.

This achieves a high insulation value over the entire height and allows the insulation and the system to be fully reused later.

| Material | Lambda value (W/mK) | Total Rd-value (m²K/W) |

|---|---|---|

| PUR 10 cm + screed 9 cm | 0,023 | 4,35 |

| EPS screed 10 cm + screed 9 cm | 0,045 | 2,22 |

| CircoFloor with EPS 19 cm | 0,031 | 5,59 |

CircoFloor achieves a higher thermal resistance (Rd-value) because the entire construction height, excluding the boarding, can be insulated.

Transport is a very important aspect. This was taken into account during development.

This allows for very efficient stacking and more environmentally friendly transportation.

Load-bearing capacity of one tower: 125 kg

Number of towers per m²: 144 towers

Total load-bearing capacity per m²: 144 towers x 125 kg = 18 tonnes

Load-bearing capacity including upper and lower structure: 18 tons x 2 = 36 tons/m²

Load-bearing capacity per adjustment screw: 250 kg

Adjustment screws per m²: 14 pcs

Total load-bearing capacity per m²: 7 adjustment screws x 200 kg = 1.4 tonnes/m²

Total load-bearing capacity per m²: 14 adjustment screws x 200 kg = 2.8 tons/m²

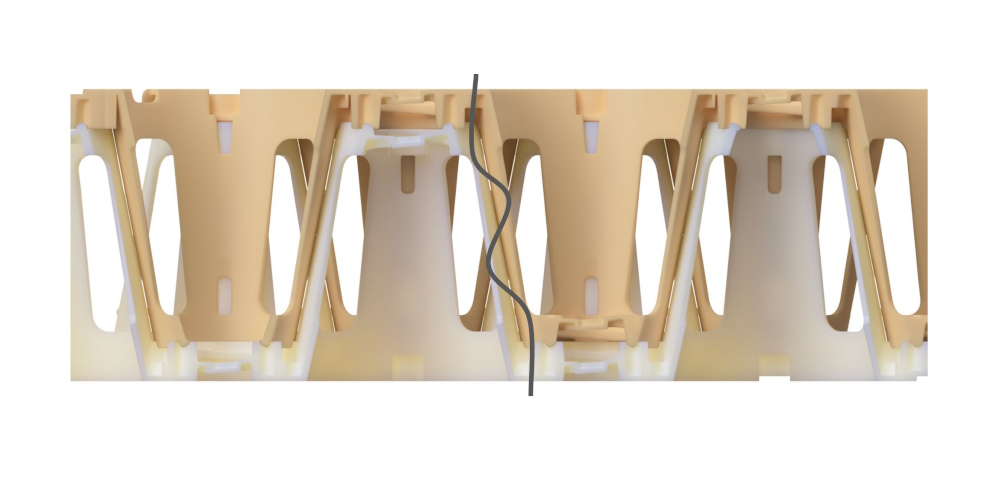

With a dry underfloor heating system, it is possible to heat your space.

These systems are suitable for both new construction and renovation and consist of insulation or gypsum fiber floor panels with pre-formed grooves in which the underfloor heating pipe is laid.

Contact

Do you also want to make a positive impact and contribute to a more sustainable future?

Then contact us! Together we will create the perfect flooring solution for your project and make a difference.

Request a quoteMore about the CircoFloor system

Click on one of the options below for more information: