Screed, Stabilized Sand, Concrete: Differences & Applications

By Staenis | 13/05/2021

What is traditional screed, what is stabilised sand, what is concrete?

Screed, stabilized sand, and concrete all contain sand, cement, and water. Each of these mixtures is used when installing floors and pavements. But what is the difference? What is screed, what is stabilized sand, and what is concrete? And for which applications are they best used? A crash course.

What is stabilisé?

You have probably already heard about stabilisé, but what exactly is stabilisé? Stabilisé is a commonly used term for stabilized sand. This mixture consists of cement, sand, and some water. Because stabilisé is quite permeable to water, it is often used as a sublayer for materials that are installed outdoors. Think of pavers, natural stone tiles, curbs, and paving. A stabilisé bed is made, cement mortar is spread over it, and the tiles or pavers are tapped in. However, stabilisé dries out quickly, which means the processing time is quite short (about three hours). By adding a retarding agent, you can extend the processing time by several hours.

Tip: If you want to finish your terrace with ceramic tiles, it is best to glue them. In this case, you need to use screed and let it dry first, so that the tile adhesive can adhere properly. On ceramic tiles, mainly only tile adhesives with additives will adhere. Because screed still lets some water through (but much less than stabilisé), you still risk frost damage and stresses in the screed. If you want to avoid the risk of damage from moisture or stresses, you can use the Staenis screed grid with drainage mortar as infill. The screed grid divides the screed in such a way that the stresses are greatly reduced. This way, you don't need a drainage mat or decoupling mat. Discover all the technical advantages of the Staenis grid.

What is screed?

If you have never built or renovated before, you might be wondering: what is screed? A screed forms the strong and indispensable base for almost all floor finishes, such as floor tiles, laminate, parquet, and fitted carpet. Furthermore, a screed (also known as a subfloor) protects the utility lines and ensures a long lifespan for your floor. Just like stabilisé, screed is a mixture of sand, cement, and water. Screed can be cement-based, like traditional screed, or gypsum-based. There are therefore different types of screed: traditional screed, anhydrite liquid screed, cement liquid screed, and insulating screed. Read more about the composition of screed, discover the right floor build-up for your project, and learn how to easily lay your own screed with a handy DIY system.

What is the difference between screed and stabilised sand?

Difference 1: a different ratio of sand, cement, and gravel

Screed has a ratio of 1 part cement to 4 to 5 parts sand, while stabilisé has a ratio of 1 part cement to 8 parts sand.

Don’t let anyone fool you: if you don’t know the difference between screed and stabilised sand, it’s nothing to be ashamed of. Screed and stabilised sand have a lot in common. They are made from the same basic materials: sand, cement, and water. So where exactly is the difference between stabilised sand and screed? To begin with, the proportions used are different. For traditional screed (also sand-cement screed), the ratio is 1 part cement to 4 or 5 parts sand. Be aware that there are various types of screed, each with their own specific composition and applications. Discover here which screed ratios you should use for your project. For stabilised sand, on the other hand, you typically use 1 part cement to 8 parts sand. Compared to stabilised sand, you use twice as much cement and extra water. Later in this article, you’ll discover when it’s best to choose screed, and when to opt for stabilised sand.

Difference 2: stabilisé allows water to pass through

Stabilisé allows more water to pass through than screed and is therefore often used for outdoor applications.

A second important difference between stabilisé and screed is water permeability. Stabilisé allows water to pass through much more easily. That is why stabilisé is often used as a foundation for materials that are installed outdoors: natural stone patio tiles, pavers for a driveway, sidewalks, and so on. Screed, on the other hand, is much less permeable and is usually used as a solid subfloor for tiles, parquet, laminate, and so on. Good to know: screed is not the only material you can use for a floor screed. In some cases, it is better to choose (tileable) insulation screed, dry fillers, or drainage mortar. Find the ideal floor build-up for your project here and learn how to save on screed work costs.

Difference 3: screed has a longer drying time

Screed has a longer drying time than stabilisé, depending on factors such as layer thickness and ambient temperature.

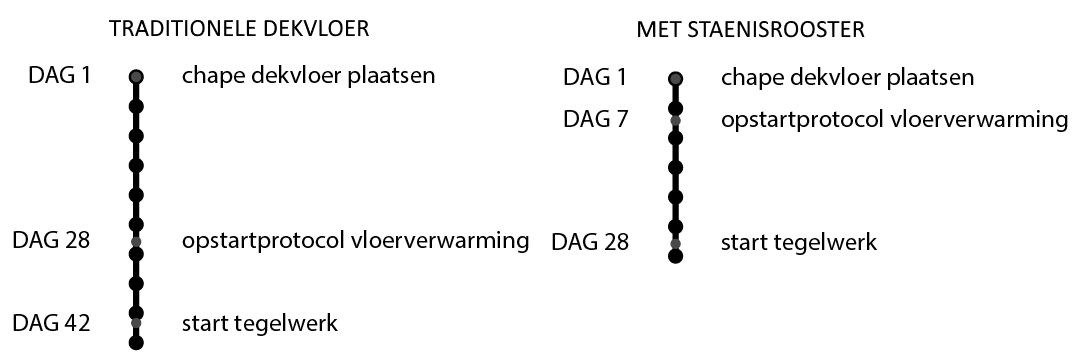

Screed is a wetter mixture than stabilisé. Consequently, the drying time of screed is much longer than that of stabilisé, although it also depends on other factors such as the thickness of the layer, the ambient temperature, and the sand used. Standard practice recommends a drying time of 28 days for a traditional sand-cement screed. Because you have to take into account the thickness of the screed, the drying time can quickly increase to 56 days for a screed of 8 cm thickness. To speed up the drying time, you can opt for fast-drying screeds. However, these are somewhat more expensive to purchase than traditional screed. Discover budget-friendly alternatives here for a shorter drying time of your screed.

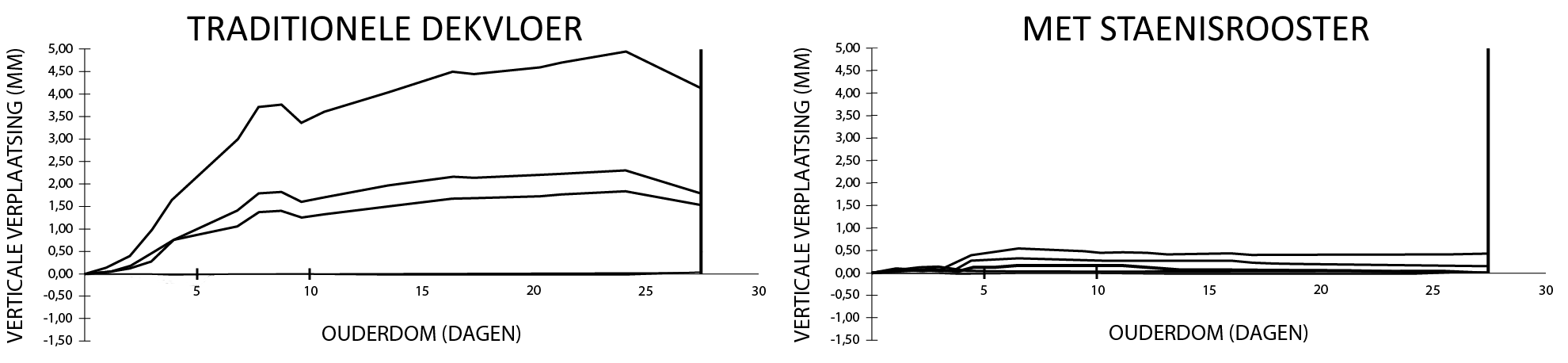

Good to know: with the StaenisGrid, a screed floor can always be tiled after 28 days, regardless of its thickness and the presence of underfloor heating. But there is more. A traditional screed floor with reinforcement mesh or fibers can become up to 5 mm uneven at the corners within a month after installation, but with the StaenisGrid, your floor always remains beautifully flat and perfectly in place. This allows for faster, easier, and risk-free installation of floor coverings.

Difference 4: a different approach to creation

When making screed, you first mix sand and cement and then add water, whereas with stabilized sand you can mix everything at once.

When making screed, you first mix the sand and cement, and then add water afterwards. When making stabilisé, you can mix everything at once. Learn here how to make screed. If you need to screed a large area, it’s better to have a screed silo with ready-made screed delivered to your site. Curious how much screed you need for your job? Find the ideal floor build-up for your floor here and use the handy quantity calculator.

Difference 5: other applications

Stabilisé wordt gebruikt als opvulmiddel en onderlaag, terwijl chape dient als stevige ondervloer voor diverse vloerafwerkingen.

Stabilisé and screed each have their applications. When should you use screed, and when stabilisé? Stabilisé or stabilized sand is a drier mixture than screed and is mainly used as a filler. It serves as a sublayer for pavers, as a supplement under foundations, as an anchoring agent for posts, or as a filler around an in-ground swimming pool. Screed cures better but is not very permeable to water. Screed is therefore ideal for indoor use, but is also useful outdoors when gluing tiles. Indoors, it serves as a substrate for various floors, on which you can directly place your floor covering. Outdoors, you can use screed for the drainage of a flat roof or terrace. With this material, you create a slope towards the drain, on which you can place insulation or waterproofing. Note: laying screed is specialist work. A screed must be placed on a solid load-bearing floor, have a certain thickness or height, and be level. Leave the job to an experienced screeder then? Not necessary. With the help of the Staenisrooster, you can easily lay your own screed, even if you have no experience.

Tip: For installing a tiled terrace, a tiled driveway, or the foundation of a garden house, it is best to use the StaenisGrid in combination with drainage mortar. With this combination, moisture and stresses have no impact on the lifespan of your new floor and you ensure a good floor structure. Discover here which floor structure is suitable for your outdoor paving.

What is concrete?

Concrete consists of sand, cement, gravel, and water. So your question 'What is the difference between screed and concrete?' is immediately answered. But there is another important difference between screed and concrete. Concrete is used for different applications than screed. For example, you can use concrete for a load-bearing floor, which fulfills the load-bearing function of a floor and provides stability. A film is placed on the bare earth, on which a concrete slab is then poured. On a concrete load-bearing floor, a bonded screed can be applied directly when the substrate is not porous, and when there is no risk of cracks and rising damp. Discover the ideal floor structure for your project here.

A popular composition of concrete for a load-bearing floor is: 1 part cement, 2 parts sand, and 3 parts gravel. The water portion is about one tenth of the solid parts. A leveling layer for the pipes is done with screed, insulation screed, sprayed PUR, or with dry fillers.

In addition, concrete can also serve as a top layer. Solid concrete floors consist of a solid concrete layer, making a screed unnecessary. Indoors, concrete floors must be at least 7 cm thick, and for outdoor applications at least 15 cm. Polished concrete floors are the most common, but you can also choose printed concrete, an exposed aggregate concrete floor, or a brushed concrete floor.

Screed or concrete?

A cement screed floor or chape is not the same as a concrete floor. The main difference is that a cement screed floor is a screed, while a concrete floor serves as a finished floor. A concrete floor consists of cement, possibly with lime. The concrete is poured onto a level, stable subfloor and serves as the finishing layer of your floor. If you opt for a sleek concrete floor, pipes for sewage, electrical supplies, gas, etc. can normally be embedded in the concrete floor. However, you must encase them with PVC. Central heating pipes and water pipes do not need to be embedded, but must be provided with a conduit that is at least 1 centimeter thicker than the pipe itself. So when you ask the question 'Screed or concrete?', the answer is: it depends on the purpose. If you need a screed, then screed is the logical choice. For a durable and seamless finish of your floor or a foundation, concrete is a suitable option.

What is screed, what is stabilised sand, and what is concrete? You discovered that, among other things, the composition and the ratio used differ, which gives each mixture its specific applications. Fortunately, there is the handy floor build-up tool, which quickly helps you discover the ideal floor build-up for your project. Each time, you use the StaenisGrid, a convenient DIY system that makes it easy to lay your own screed. You can order your required materials online, in the Staenis webshop.